Environmental Engineering Reference

In-Depth Information

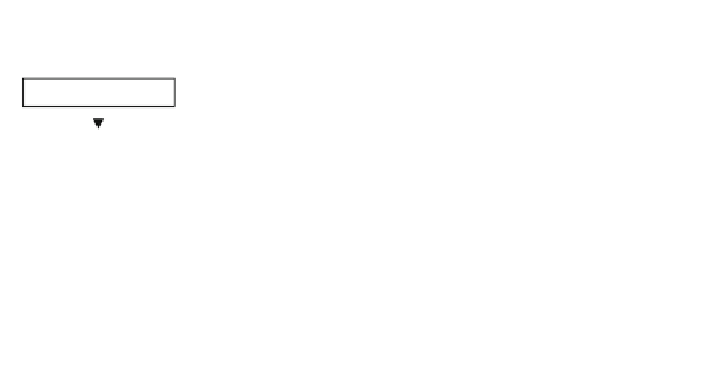

Recycling and climate balance

Development

Production

Use

Disposal

Build recoverability

into design

Rubber recycling

and reuse

Waste collection

system by dealers

Using shredder

residue effectively

Resin recycling and

reuse

Replacing and re-

manufacturing parts

Battery recycling

system

Design for recycling

Use of recycled

materials

Fig. 15.7

Recycling and climate balance

vehicles, such as steel and aluminum, light plastics, composite, and fiber glass

strengthened materials are increasingly used and recycling them requires a specific

technology; see Fig.

15.7

[

42

].

Light construction plastic materials on average require a higher level of energy

in the production process than considerable metal products. That is the reason why

plastic elements of road vehicles, airplanes, and ships are usually difficult to

recycling and need a very long time to decomposing. There are still a lot of open

questions for future development in production and recycling of light construction

materials.

15.6.2 Recycling of Airplanes

As airplanes are very expensive, most of them are typically leased for 20-40 years.

Very few go back into service after a long lease because evolving aerospace

technology leaves older airplanes unable to compete against newer airplanes,

which can be operated at a lower cost with decreased fuel consumption.

To protect the environment, professional decommissioning and recycling of

older aircraft will increase in the future. There are no regulations for recycling

airplanes. Many of them stay in the desert. Expensive equipment for aircraft, e.g.,

navigation and safety devices are often collected and utilized in special second

uses [

43

].

The self-obligation of aviation companies is moving in the right direction.

Many of them wanted to realize 50% recycling or more. In the future, legislation

should be similar to cars and 90-95% of all parts of an airplane should be recycled.

Search WWH ::

Custom Search