Geology Reference

In-Depth Information

9.4.2

Evaluating new telemetry concepts.

In existing tools, the turbine is located beneath the pulser because it is

(incorrectly) believed that it would otherwise block the MWD signal from

traveling uphole. That little or no reflection at the turbine occurs is easily

verified in the long wind tunnel and should be apparent from its large “see

through” area. This opens up numerous possibilities for telemetry design.

Earlier we discussed the use of constructive wave interference for signal

enhancement without incurring the usual erosion and power penalties. A siren

placed nearer to the drillbit would also allow faster wave reinforcement and, by

implication, higher data rate. As we have seen in Chapter 2, the drilling

telemetry channel should support frequencies much higher than the 12 - 24 Hz

range currently used; in Chapter 10, we cite independent confirmation that much

higher frequencies can be transmitted in the drilling channel. A higher

frequency, aside from increased data rate, would be beneficial because MWD

signals can be more easily distinguished from slower acting mudpump noise.

Standard frequency filtering can be used for preliminary signal processing.

9.5 Water and Mud Flow Loop Testing

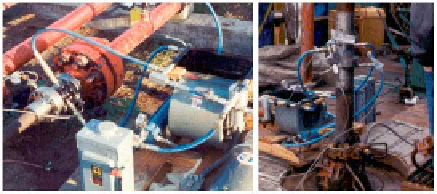

The use of a ruggedized steel test fixture for the wind tunnel system in

Figure 9.12a should be noted. This was designed so that tests performed in wind

can be effortlessly repeated in mud loop and field tests, for instance, as shown in

Figure 9.17. The siren control and signal processing station in Figure 9.13 was

developed with the same philosophy in mind. Signal processing algorithms and

telemetry tests planned and programmed in software for the wind tunnel are

transferred to the field with minimal modification. Since actual test times are

small compared to “down times” typically encountered in setting up equipment,

our approach makes optimal use of expensive test resources and labor. From

this author's experience with wind tunnel and mud loop testing, wind tunnel

problems can be diagnosed and solved much more quickly than those arising in

the field, because plumbing issues like leaks, blown hydraulic lines, opening and

closing flanges, and simply “getting wet” do not arise.

Figure 9.17.

Wind test fixture used in mud and field tests (Gardner, 2002).

Search WWH ::

Custom Search