Geology Reference

In-Depth Information

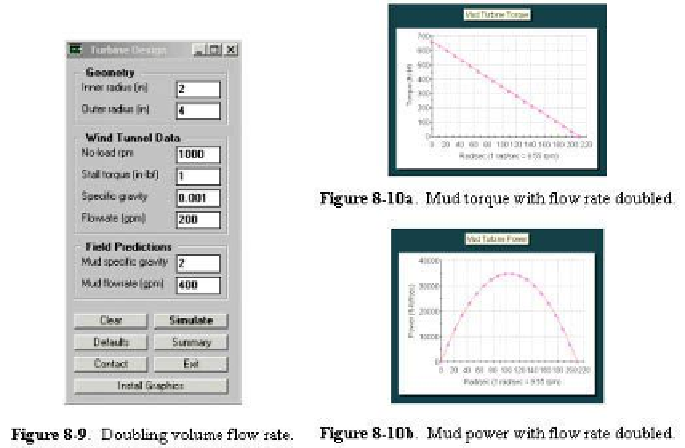

In summary, we have described relationships for physical variables

important to turbine design and demonstrated their implementation in

“turbine.exe” (the Fortran engine is contained in calc-5.for). As noted, once

geometric parameters and wind tunnel test results are entered, the program plots

wind tunnel performance curves; also, for mud densities and mud flow rates

chosen by the user, the program will plot the corresponding torque and power

curves versus rotation rate.

Formulas for the two turbine rotation rates that correspond to a fixed level

of desired power are given in Equation 8.6 while the maximum power available

is given in Equation 8.7. Again, the numbers used to demonstrate the software

do not represent real tests, but were selected for illustrative purposes only. We

emphasize that it is not important to run wind tunnel tests at any particular

speed, so long as that speed can be measured accurately; our conversion routines

provide mud results whatever wind speed is used in the testing. Our fast

calculations are almost instantaneous and do not involve iterative methods.

Finally, we give examples from actual MWD turbine hardware tests in

mud, to augment our discussions on wind tunnel measurement in the laboratory.

Figure 8.11 plots stall torque versus flow rate and correctly shows a parabolic

dependence on speed. Figure 8.12 plots no-load rotation rate versus volume

flow rate - measurements for a steel turbine in mud and a plastic mockup in air

correctly fall on the same straight line. Also, the power curves in Figure 8.13

clearly follow the inverted parabolic trend as do measured data. Torque results

in Figure 8.14 for mud and air agree with predicted straight-line trends and

correctly scale with “UU

2

” as is demonstrated from theory.

Search WWH ::

Custom Search