Image Processing Reference

In-Depth Information

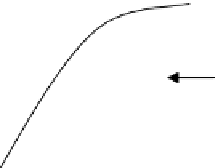

Linearizing curve of DMA on

photoconductor or

Δ

E

from paper

from which TRC curve for single

separation is determined

100%

D

DMA on Photoconductor

or

Δ

E

from paper normalized

to a maximum value of

100% or 255

C

B

The TRC of DMA on

photoconductor or

Δ

E

from paper

E

0

100%

E

A

Area coverage scaled to a

maximum value of 100% or 255

FIGURE 9.21

Schematic diagram illustrating graphically the static TRC inversion process

shown for one measurement point at area coverage A when the measured tone value is greater

than the reference tone value.

input area coverage A at which the measured tone value on the TRC is equal to D and

the output tone value on the reference TRC is calculated as B. The tone value

on the reference TRC is calculated by simply drawing a vertical line until it intercepts

the reference curve. Now, to

find the tone value on the inverse TRC for area

coverage A, draw a horizontal line (toward right in Figure 9.20 and toward left in

Figure 9.21) until it intercepts the actual TRC. The output tone value at this intercept is

indicated by C (this is also equal to B), whose input area coverage (or tone value) will

be equal to E. Thus, E becomes the tone value on the inverse TRC at area coverage A.

This process is repeated until all the input area coverages have tone values on the

inverse TRC.

This type of inverse TRC has bene

ts for full range of tone control from 0% to

100%. In a digital printing system, since every pixel in the image that contains

input contone values is processed through the inverse TRC of the level 3 controller,

the

final curve should be smooth and free of undesirable curvatures or artifacts

introduced during the inversion process. If not, image quality defects or

image noise in the output images may occur, and these are not acceptable for

high-quality color printing. While the process of constructing

static inverse TRC

''

looks simple, many practical considerations require attention. For example,

the measurement noise could be different for low area coverage (highlight) patches

as compared to high area coverage (shadow) patches, which can induce undesir-

ably high-frequency structure in the inverted TRC. The rounding of values

between 0 and 255 can also introduce errors which can further sacri

''

ce inversion

accuracy. Since the real goal of level 3 controller is to linearize the tone response

on paper to control the appearance of images on paper, paper-based measurements

may be more desirable than those on the photoconductor. The area coverage

selection for paper-based measurements may be different from those used for

measurements on the photoconductor. We will show later how an optimal

Search WWH ::

Custom Search