Environmental Engineering Reference

In-Depth Information

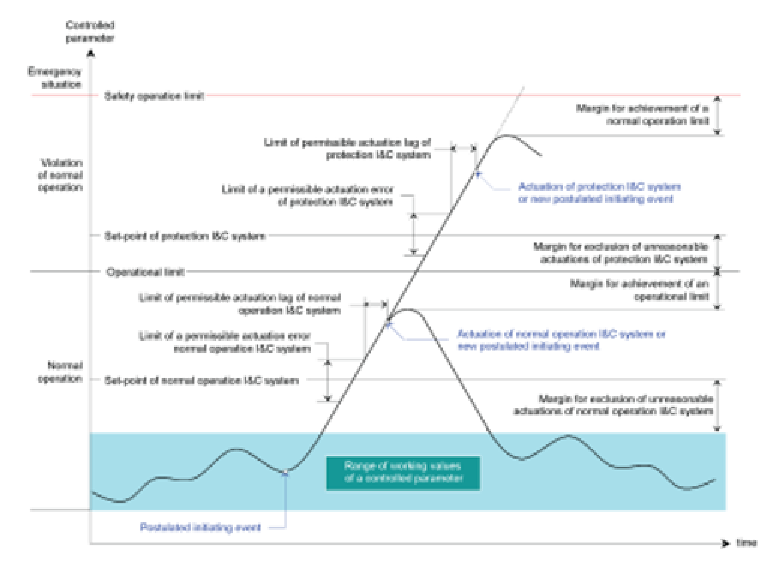

Figure 4. Design limits and selection of set-points of I&C systems

In case of operational events the safety actua-

tion I&C system:

• Archives data of commands, obtained from

the safety protection I&C system, normal

operation I&C systems and operational

personnel, results of automatic diagnostic

and detected operability failures of own

components and adjacent equipment.

• By commands from the safety protection

I&C system forms and issues control sig-

nals to actuating elements of technologi-

cal systems and equipment (gate valves,

pumps, electric motors, control valves,

сontrol rod drives, etc.) required for per-

formance of protective actions initiated by

these commands.

• Prohibits execution of commands that can

be issued by other protection I&C sys-

tems, normal operation I&C systems and

/ or operational personnel in case they are

not compatible with executed protective

actions.

• Displays information required for opera-

tional personnel to control executed actions

and if necessary perform remote control of

technological equipment.

•

Forms and issues messages to other I&C

systems about condition of operation of

own components and adjacent equipment.

For each safety actuation I&C system the fol-

lowing is defined in the design: a list of sources

of commands (safety actuation I&C systems,

normal operation I&C systems, equipment of main

control room and / or emergency control room); a

list of command receivers (actuating elements of

technological systems and equipment); algorithms

for formation of control signals required delays

of output and / or withdrawal of control signals

(if necessary); compliance of logic conditions of

each discrete output signal with values of physical

Search WWH ::

Custom Search