Information Technology Reference

In-Depth Information

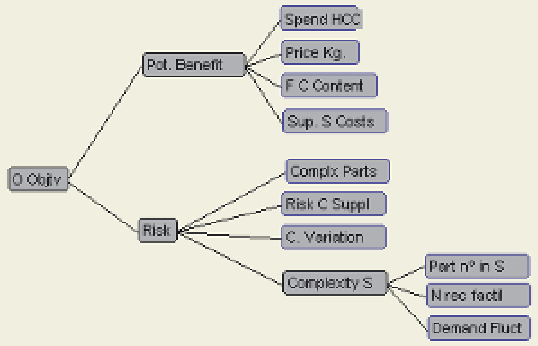

On the other hand,

Risks

is split into four sub-objectives.

Complexity of parts

(Complx Parts)

represents part of the risk of selecting a new supplier. Technical issues related to quality and

material specification could be added to the assessment of the total complexity of parts in

each segment. A higher complexity implies a higher risk.

Risk with current suppliers

(Risk C

Suppl) quantifies the number of segments that the supplier is supplying at that moment.

Moving business in one segment from the current supplier to LCC will influence the supply

of the other segments (price increases, production stop pages, low performance, etc.).

Therefore, the more segments supplied by one supplier, the higher the risk of moving to

LCC.

Fig. 9. Objective hierarchy to create a cost efficient production process

The

Coefficient of variation

(C. Variation) tells us how homogeneous the price per kg of the

parts in the segment is. The higher the coefficient of variation, the greater the risk, because

the handling of the different parts of the segment varies more. Finally,

Complexity of segments

(Complexity S) represents supply chain issues in relation to the purchase of parts from a

wider perspective. The

Number of parts within a segment

(Part nº in S), the

Number of receiving

facilities

for the parts in the segment (N rec facil) and

Demand

fluctuation

(Demand Fluct) are

the main quantifiable criteria to be taken into consideration. A set of 19 non-metallic product

segments was identified. Their performances in terms of the 10 attributes under

consideration are reported in (Table 2, Jiménez et al., 2005).

Fig. 10. Imprecise linear piecewise utility function for the

Total annual expenditure

Search WWH ::

Custom Search