Information Technology Reference

In-Depth Information

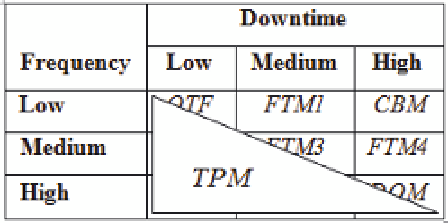

operation (high downtime). Machines in this region should be monitored closely. It

is a good idea to equip the machines with sensors or any condition-based

monitoring devices to observe their performance;

d.

Design-out maintenance (DOM): Machines that always fail (high frequency). Once

failed, it takes a long time to bring them back to normal operation (high

downtime). This region consists of the worst production machines and it is

recommended that they be structurally modified. A maintenance department

should consider a major design-out project and spend money to upgrade the

machines in this grid; and

e.

Fixed time maintenance (FIM): There are five categories as follows:

FTMI: Concern about the timing of the maintenance. Maintenance department

should revise when is the best time to conduct the preventive maintenance;

FTM2: Maintenance department should study who is the most suitable person

to conduct the maintenance job for those machines in this grid, i.e. operator,

technicians, contractors or maintenance engineers;

FTM3: Failure frequency and downtime are almost at the moderate cases,

FTM4: Maintenance department should revise on their maintenance checklist

and instructions. What are the instructions that must be included during

maintenance; and

FTM5: Maintenance department should revise on how the maintenance should

be conducted and improved.

The TPM approach should be applied for the lower triangle of the DMG matrix, as

shown in Table 2 (Labib, 1998b). TPM is applied globally and one of the TPM

concepts is to empower the operators to maintain continuous production on totally

efficient lines (Nakajima,1988). TPM is the continuous knowledge transfer to

operators and the maintaining of the production equipment together with the

maintenance crew. Hence, we can slowly reduce the waiting time for technicians to

be in the production plant. On the other hand it gives operator the opportunity to

eliminate the root causes of the machines' errors on a small level, before they

become big ones.

Table 2. DMG-TPM Strategy (labib 1998b)

The RCM approach should be applied for the upper triangle of the matrix as shown

in Table 3. RCM involved a study and measurement of the probability that a

machine will operate as expected at the desired level, for a specific period of time,

under the design operating conditions, and without any failures. Once the

problematic machines are identified, the maintenance strategy should be adjusted

to ensure the longest survival of the machine to complete a mission at a specific

Search WWH ::

Custom Search