Information Technology Reference

In-Depth Information

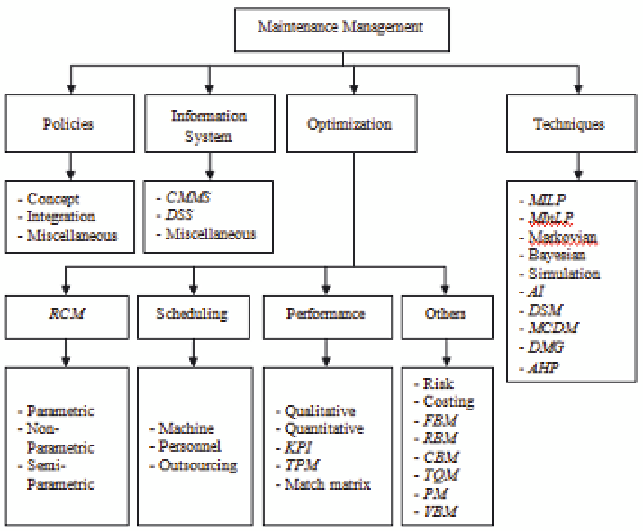

Abbreviation represent: CMMS: Computerized Maintenance Management System; DSS: Decision

Support System; RCM: Reliability-centred Maintenance; KPI: Key Performance Index; TPM: Total

Productive Maintenance; FBM: Failure-based Maintenance; RBM: Risk-based Maintenance; CBM:

Condition-based Maintenance; TQM: Total Quality Maintenance; PM: Preventive Maintenance; VBM:

Vibration-based Maintenance; MILP: Mixed Integer Linear Programming; MInLP: Mixed Integer non-

Linear Programming; AI: Artificial Intelligence; DSM: Decision Support Model; MCDM: Multiple

Criteria Decision-Making; DMG: Decision-Making Grid; and AHP: Analytical Hierarchical Process

Fig. 1. Sub-division Tree of Maintenance Management

4.1 Maintenance policies

Guy and Steve (1999) reviewed the general terms of maintenance. They studied

maintenance development and the reason behind it changing from time to time. After that,

they focused on the enhancement and evolution of information systems in maintenance.

Some important findings on enhancement of the development of information systems in

maintenance are given, as they have discovered that new strategic development in

maintenance is due to information system application and development.

Lam and Lin (2004) integrated some replacement policies into corrective maintenance.

Corrective or Failure-based Maintenance (FBM) is unscheduled maintenance or repair to

return the machine to a defined state. There are no interventions until a failure has occurred.

Lewis (1999) addressed corrective maintenance as reactive maintenance, where any

emergency breakdown will lead to a bigger impact on the operation. Since the failures are

unplanned, they might result in a big loss to the organization in terms of cost and time.

Therefore, a better maintenance concept must be introduced to prevent this unplanned

downtime and reduce the cost of the failure. The breakdown maintenance concept is still

applied to equipment that is not mission critical and where the downtime would not affect

the main operation of the organization, such as light bulbs and consumable parts. Lam and

Lin (2004) have introduced some numerical methods and designed optimal replacement

policies in FBM.

Search WWH ::

Custom Search