Information Technology Reference

In-Depth Information

Efficient farming of animal husbandry on such an industrial scale relies largely on several

variables and limitations that are normally correlated. In such a situation, characterized by

multiple scattered farms that depend on a centralized supply centre, there are two main

subjects to take into account: (

i

) different breeds of poultry growing in the same farm (many

animals) with a distinct raise program and (

ii

) different types of feed needed for each lot in

each farm for a given period of time. In order to build an appropriate knowledge base for

the accurate operation of the SP4 system, several economic, production and management

company databases were studied and pre-processed. The main objective was gathering and

filtering real data in order to obtain a valid history of feed orders sent to farmers during

recent years. Table 1 presents the final structure of the cases comprising the memory of the

SP4 system. The general criterion applied for the development of the SP4 internal case base

was to select those orders sent to the farmer in the period comprising four days before each

lot arrived at the farm, until its exit. During this process, several rules were codified and

applied for detecting and solving existing inconsistencies.

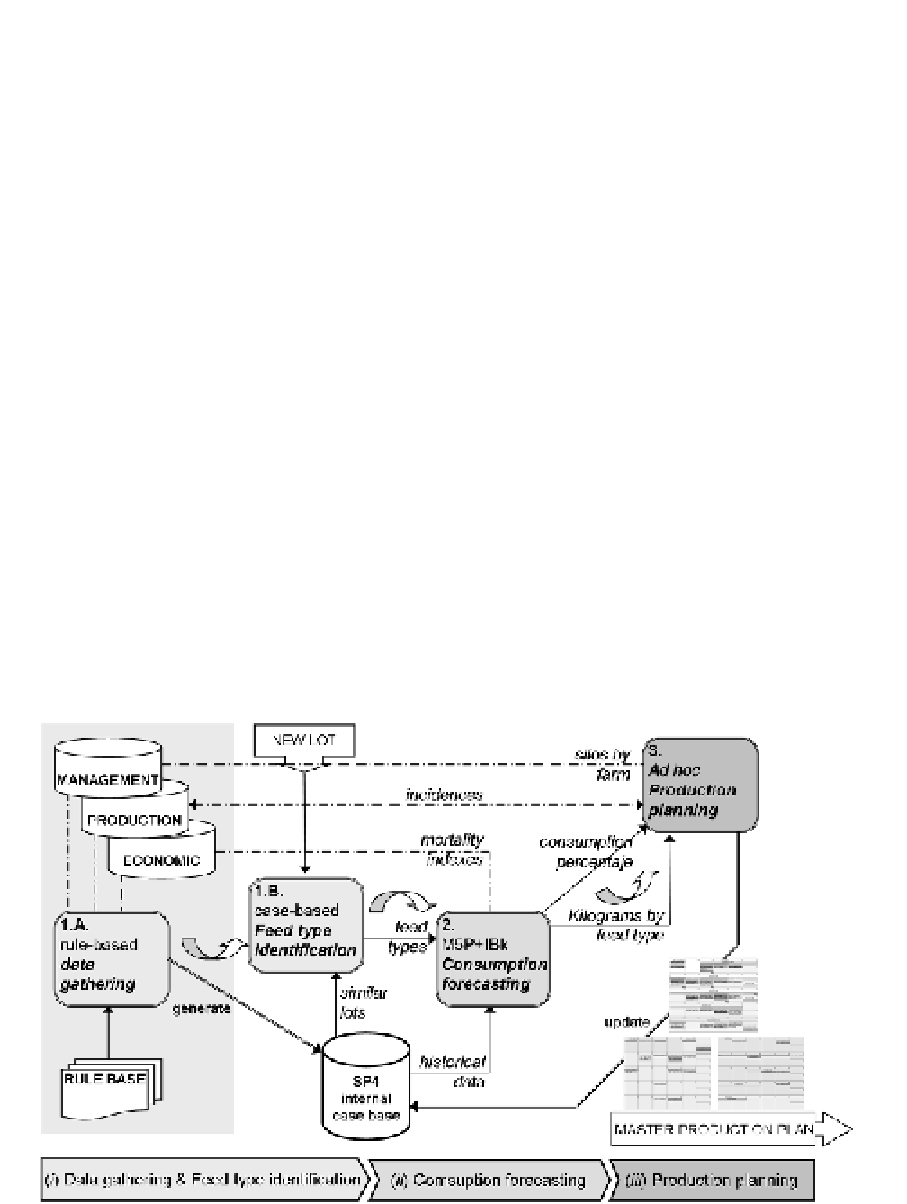

Given the large number of variables and rules that play an important role in the whole

process of correctly supplying feed for all the farms comprising a given cooperative, the

proposed decision support system has been organized into three different but

complementary subsystems: (

i

) data gathering and feed type identification, (

ii

) consumption

forecasting and (

iii

) production planning. The developed system is going to execute

subsystems one and two in a sequential fashion for each new lot of animals that arrives to a

given farm. Finally, subsystem three is responsible for combining all this information on a

daily basis and determining the amount of feed that must be produced by day and type to

the main feed production plant. Figure 3 depicts the general architecture of the SP4 system.

As it can be seen from the operational diagram showed in Figure 3, each subsystem works

with unrelated information coming from both existing data and knowledge bases, but also

considering the output of the previous stage. In the proposed architecture, each phase solves

a different problem following a bottom-up approach.

Fig. 3. General architecture and life cycle of the SP4 system for compound feed forecasting

and planning

Search WWH ::

Custom Search