Information Technology Reference

In-Depth Information

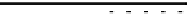

MAGNETS

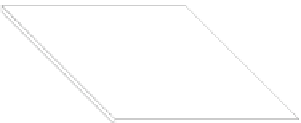

C)

B)

ELECTRODES

PADS

A)

E)

D)

PZT SUBSTRATE

Fig. 17.

(A) Structure of the proposed circuit demonstrator. Two interdigitated elec-

trodes are fabricated on a PZT layer. Magnets are located in the area between two

electrodes arms. Contact pads are used to apply the voltage to the structure. (B) Fab-

rication Process. Fabrication of the PZT through sol-gel techniques. (C) Electrodes

fabrication through direct laser writing lithography. (D) Deposition of magnetic mate-

rial through sputtering and patterning of magnets through EBL or FIB lithography.

(E) Optional removal of magnetic material from the electrodes structure.

pattern the magnetic material to obtain magnets and to remove the magnetic

material in excess to avoid unwanted contacts between electrodes. The magnetic

material is normally a conductor so, also if it covers the electrodes, there will

be an electric contact. However, magnetic materials are normally bad electrical

conductors, so to improve the structure an optional step (Fig.

17

(E)) can be used

in order to remove the magnetic materials directly above the electrodes. Clearly

the area where magnets are located must be properly masked in the process.

Due to technical limitations we have not obtained the complete structure

yet, however in Fig.

18

we can illustrate some preliminary results. Figure

18

(A)

shows a scanning electron microscope (SEM) image of the electrodes structure.

It is possible to observe the contact pads and the electrodes. Arms of the two

electrodes are alternatively interleaved, in this way there will be a strain between

each couple of arms. The maximum resolution that we can currently obtain

with our lithography process is 2

m, so, as it is possible to note from Fig

18

(B),

electrodes sizes are in the micrometer range. These sizes are much bigger than the

desired ones, however, they are enough if the purpose is the demonstration of the

effective magnets reset and switching. Figure

18

(C) shows instead a SEM image

of a typical PZT substrate [

33

]. It is possible to observe its typical grain structure,

with grain sizes in the range of a hundred nanometers. The average roughness is

around 3 nm. Figure

18

(D) shows instead a film of Iron-Terbium. Iron-Terbium

is a material similar to Terfenol with high magnetostriction that we are studying

since our studies in [

107

]. Its surface is pretty rough for the moment and the

thickness is quite high: 500 nm. Our efforts are now concentrated on the creation

of thinner films with a lower roughness and its deposition on the PZT layer.

In the meantime we are using Nickel as magnetic material for our experiments.

Normally, an interface layer is used between the PZT and the magnets [

34

]. This

approach reduces the mechanical coupling so we are trying to avoid this choice,

depositing the magnetic layer directly on top of the PZT.

µ

Search WWH ::

Custom Search