Information Technology Reference

In-Depth Information

66000

65000

64000

63000

62000

61000

60000

59000

58000

57000

56000

55000

54000

53000

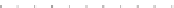

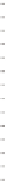

0 1 2 3 4 5 6 7 8 9 10 20 30 40 50

Optimisation

Fig. 3.

Experimental Results

implementation has been integrated with

ContMAS

as an “advisor”: when machines

bid for container moves in

ContMAS

, they may consult the prepared schedule, and use

this to guide whether they submit bids or not.

We now briefly present some (initial) experimental results. These were derived using

real (anonymised) data from January 2009, extracted from the JMT system used by the

local port, with only data fitting our simplified scenario being used (unloading only,

using only one area in the yard, and with no yard-to-yard moves considered). We used

data for a single ship being unloaded, which involved 82 containers, 3 Quay Cranes, and

8 straddle carriers. Figure 3 shows the solution quality (i.e. its cost: smaller is better) as

the optimisation step is repeatedly applied. As can be seen, the initial solution resulting

from the initial allocation phase (at x=0) is improved by the first few optimisation steps.

Each point in Figure 3 is the average of ten runs.

6

Optimisation of Container Yard Allocation

The placement of containers in the yard can make a big difference to the cost of moving

the container later to where it is needed. However, yard allocation is complicated in

practice by various uncertainties. For instance, ships sometimes do not arrive at all and

all of the containers scheduled for a particular voyage must then be rebooked on other

vessels or returned (if that is possible.) More significantly for yard operations, those

remaining containers may now be obstructing access to containers for later voyages.

Additionally, tide or weather conditions may result in a ship being berthed with a re-

versed orientation — with the bow being where the stern was expected. As the loading

sequence depends on the orientation this can create a significant problem of overstows.

For these reasons most prior research (see Section 3) has addressed various sub-areas

within the overall problem of optimising container locations within the yard. This prior

research indicates that simplified variants of the Yard Allocation Problem are amenable

to optimisation, however no single approach to date has addressed the complete prob-

lem. Note that this is a multi-objective problem with many, often conflicting, constraints

to be satisfied. To try to tackle this task we have implemented an optimisation interface

within

ContMAS

that allows a variety of approaches to be tried.

Agents that need a yard location in which to store an incoming container make a

request of a

BayMapOptimiser

agent, which calls one of potentially several optimisers.