Environmental Engineering Reference

In-Depth Information

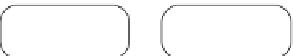

Emissions from

transfer

Hot metal

Charging

emissions

Emissions from

oxygen blow

Emissions from

slag removal

Emissions from

skimming

Torpedo car

transfer

Baghouse

Electrostatic

precipitator

Baghouse

No control

Hot metal

desulfurization

Baghouse

Additives

Slag

skimming

Hot meta

l

Slag

Basic oxygen furnace

Deslagging

Baghouse

Scrap

Flux

Desulfurization

emissions

Molten

steel

Additives

Oxygen

Slag transfer,

disposal

Transfer to

continuous

caster

Ladle

treatment

Tapping

Alloys and

other additives

Cast steel

None or

water spray

Baghouse

None

Baghouse

Caster emissions

Emissions from ladle

metallurgy

Emissions from tapping

Emissions from slag

transfer,disposal

Fig. 3.12 Sources of nanoparticles in a steel plant in Michigan (USA) [

51

]

Ca-P-Si tertiary system, which demonstrated that the ions resulted mostly from the

coal flying ash. This proved the optimisation/minimisation of the solid aerosol

content of the coal flying ash added to the alternative dust fuel in fluidised bed

coal-fired thermal power plants [

48

-

50

].

3.3.1.2 Ferrous and Non-ferrous Metallurgy

A recent thorough study on several steel plants with coke oven batteries in the Great

Lakes area reveals both direct sources of PM

2.5

(Fig.

3.12

) and sources that generate

nanoparticles through

de novo

synthesis between PAH and the heavy metals

released in the atmosphere (Fig.

3.13

)[

51

].

The total amounts of PM

2.5

released from the steel plants are given in

Table

3.8

[

51

].

The above-mentioned experimental data indicate that these amounts must not be

ignored, especially because they include heavy metals under the form of both

organic and organometallic compounds that are very dangerous for health and the

environment.

As far as the orientative distribution of iron-containing nanoparticle concentra-

tion in large steel plant areas is concerned, the concentrations measured in various