Environmental Engineering Reference

In-Depth Information

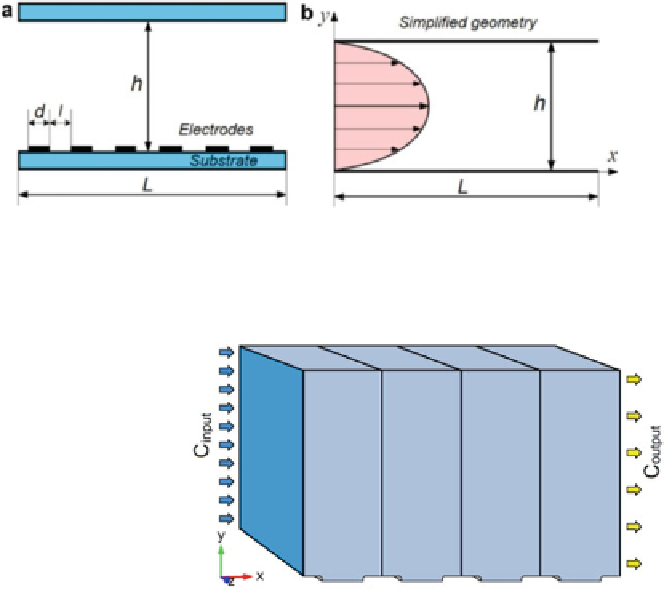

Fig. 14.14 Schematic representation of a dielectrophoretic chamber used for DEP separation (a),

and the simplified geometry used as computational domain for the computation of the concentra-

tion field (b)

Fig. 14.15 Schematic

representation of the

separation device revealing

the parameters used for

defining the

Filtration rate

as presented in Fig.

14.14b

. In the latter case, one can assume that the flow field is

described by a classical Poiseuille profile [

8

].

For a given DEP-force and fluid flow field, the particle concentration is evalu-

ated by numerically solving the equation system (

14.26

)-(

14.27

). This calculated

particle concentration field gives information at a local scale, showing how the

particles are attracted on the margins of electrodes and the influence of the main

parameters of the problem on this process. For the analysis of the filtration process

we define the novel quantity named

Filtration rate

(

F

), which describes the process

in terms of nanoparticles entrapment at the electrodes, related to the concentration

distribution [

49

,

50

]:

C

input

C

output

C

input

F

¼

¼

C

output

=

C

input

½

ð

:

Þ

1

14

28

where

C

input

and

C

output

are the mean concentrations of suspended nanoparticles at

the input and the output surfaces of the device, respectively, as schematically

sketched in Fig.

14.15

.

This proposed quantity gives the global information on the filtration process, and

can be used in order to evaluate the efficiency of the filtration process.