Environmental Engineering Reference

In-Depth Information

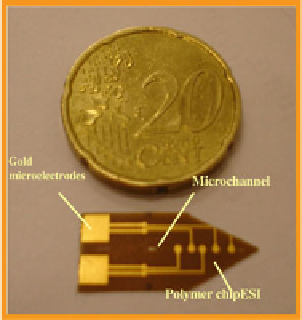

Fig. 8.4 Planar polymer

microchip for ESI produced

by DiagnoSwiss (courtesy

of DiagnoSwiss)

fragmentation of labile groups attached to the main structural backbone is mini-

mized, enhancing the sensitivity of the analysis.

Another popular category of chips for ESI MS consists of planar or thin

microchips, made from glass [

28

] or polymer [

29

] material, embedding a

microchannel at the end of which electrospray is generated in-plane, on the edge

of the microchip.

During the last years, the progress in polymer-based microsprayer systems was

promoted by development of simpler methods for accurate plastic replications and

ease to create lower-cost disposable chips. For instance, DiagnoSwiss Lausanne has

developed a disposable polymer microchip with integrated microchannels and

electrodes, which was coupled to both a quadrupole time-of-flight and a Fourier

transform ion cyclotron resonances mass spectrometer [

30

]. The chip presented in

Fig.

8.4

was microfabricated

by

semiconductor

techniques

including

photolithography [

30

].

For the microchip fabrication, the starting material was a polyimide foil of

75 mm thickness, which is coated on both sides with 5 mm copper. A photoresist

was patterned on the copper-coated polyimide foil through a printed slide acting as

a mask. Photoresist was then developed and chemical etching was used to remove

the deprotected copper where microchannels are to be patterned. Polyimide was

plasma-etched to the desired depth. As both sides of the substrate were exposed to

the plasma, through-holes were fabricated to act as sample reservoirs and/or

provide access to the microchannel. The final microchannels were 120 mm wide,

45 mm deep (nearly “half moon” cross section), with 100 mm gold-coated micro-

electrodes placed at the bottom of the microchannel (Fig.

8.5

).

A 35 mm polyethylene/polyethylene terephthalate was laminated to close the

channels. As described before [

30

] one end of each channel was manually cut in a

tip shape, so that the outlet of the microchannel was located on the edge of the chip.

For sample dispensing, either a reservoir was pasted over the inlet of the

microchannel or the chip was sandwiched in a home-made chip holder with an

integrated reservoir (Fig.

8.6

).