Environmental Engineering Reference

In-Depth Information

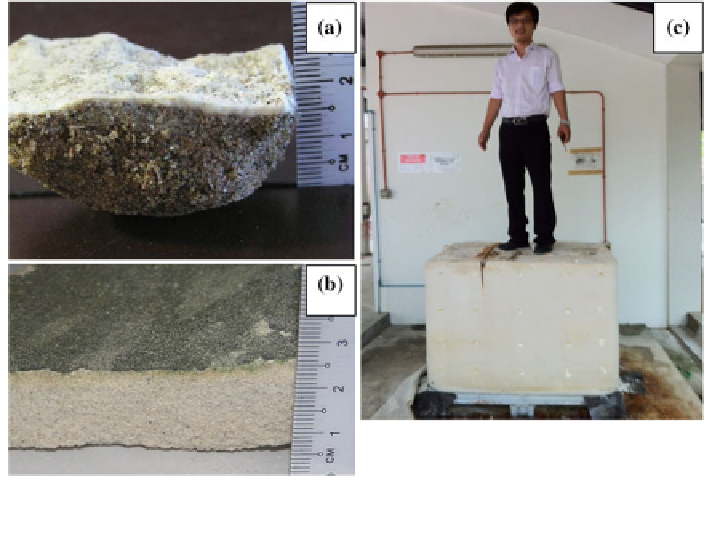

Fig. 2.6 Spatial types of biocementation: formation of the crust on surface of sand (a), formation

of the biocemented layer of the defined thickness (b), biocementation of monolith (c)

were associated with some infectious diseases (Novakova et al.

2006

; Taponen

et al.

2008

). Therefore, the isolated strain was not used for biocementation studies

and applications.

Biocementation can be performed as bulk biocementation through the supply of

bacterial suspension altogether or separately with solutions of calcium and urea by

injection, and using surface percolation (Cheng and Cord-Ruwisch

2012

; Stabni-

kov et al.

2011

) or surface spraying (Stabnikov et al.

2011

,

2013a

; Chu et al.

2012a

). Modifying types of the treatment it is possible to form the crust on surface

of soil (Fig.

2.6

a), biocemented layer of defined thickness (Fig.

2.6

b) or bioce-

mented monolith (Fig.

2.6

c).

There are several drawbacks in the conventional MICP process: (1) by-product

of urea hydrolysis is ammonium and ammonia that are toxic substances for

workers, harmful for aquatic environment and atmosphere, and increases the risk

corrosion because of high pH (Pacheco-Torgal and Labrincha

2013a

); (2) the

brittleness of calcite crystals bonding the soil particles; and (3) the cost of calcium

reagent and urea are higher than the cost of conventional cement. Therefore, the

improvements of MICP as well as new types of biocementation have to be

developed to overcome these disadvantages of conventional MICP.

Search WWH ::

Custom Search