Environmental Engineering Reference

In-Depth Information

356

300

205

0

Ordinary

Liquid &

40% Cement

-157

100%

Cement

-300

-471

100%

Aggregate

-600

-900

-1134

-1,200

TOTAL

Formulation

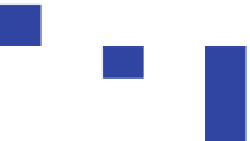

Fig. 13.3 GHG analyses of different concrete formulations where traditional components are

replaced by novel carbon-reducing carbon sequestered limestone components. The formulations

are based on a generic ''moderate-strength'' mix design that includes, per m

3

concrete, 356 kg

cement, 178 kg water and 1,880 kg aggregate (848 kg fine, 1,032 kg coarse)

twenty-first century we cannot simply assess the situation from the similar view-

point as the nineteenth and twentieth century. Considering the civil engineered

world around us is a core component to an overall sustainable future. Reducing

cement production by offsetting cement needs in concrete, using concrete as a sink

to receive captured carbon materials are solutions leading to a direction that can

solve our challenges of today and tomorrow.

Below we see the green house gas (GHG) analysis for ordinary concrete as

compared to advanced mix designs that not only reduce the amount of carbon per

yard of ordinarily mix designed concrete compared to low cement mix designs as

well as synthetic limestone inclusive mix designs (Fig.

13.3

).

A green house gas analysis of kilograms of carbon dioxide per cubic meter

(kg CO

2

/m

3

) concrete in Fig.

13.1

exemplifies that replacement of traditional

components in a concrete formulation by novel, carbon-reducing components, can

lead to a significant reduction in the kg CO

2

/m

3

concrete. If we consider that an

average of 927 kg of CO

2

is emitted for every 1,000 kg of OPC produced in

the U.S., depending on fuel type, raw ingredients and the energy efficiency of the

cement plant (Source: ''Concrete CO

2

Fact Sheet'', National Ready-Mix Concrete

Association, Feb 2012, based on the most recent survey of Portland Cement

Association members), an ordinary moderate-strength mix design has 356 kg CO

2

/

m

3

concrete; this also assumes no CO

2

contributions from the water and aggregate

components of the concrete mix design. If, for example, a carbon-reducing liquid

that contains 5 % by weight CO

2

is used as a complete water replacement, the

kg CO

2

/m

3

concrete is reduced by 9 kg CO

2

. When the carbon-reducing liquid is

used in combination with a 40 % replacement of OPC by interground limestone, the

kg CO

2

/m

3

concrete is reduced to a mere 205 kg CO

2

/m

3

(from 356 kg CO

2

/m

3

).

Search WWH ::

Custom Search