Environmental Engineering Reference

In-Depth Information

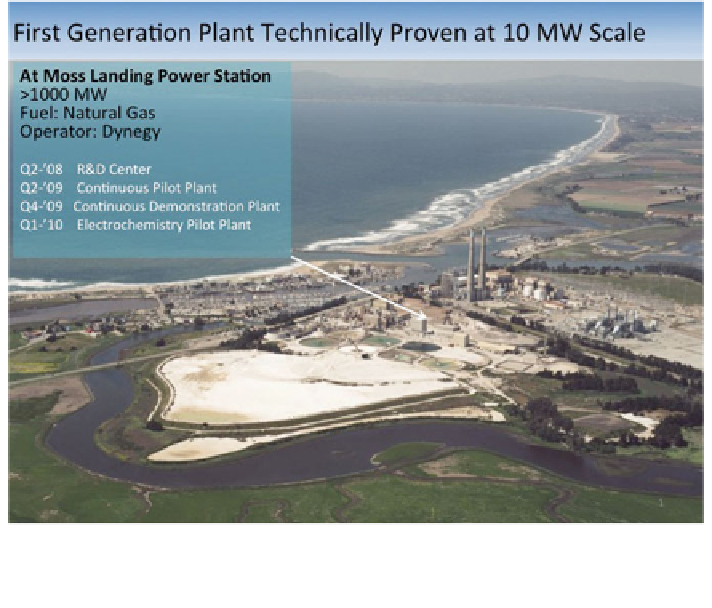

Fig. 13.2 First Generation carbonate mineralization was demonstrated at a pilot and demon-

stration scale between 2008 and 2010 in Moss Landing, California, using flue gas from the Moss

Landing Power Station, the largest operating power plant on the west coats of the United States

13.3.2 Calcium Carbonate Cements

A diverse variety of calcium carbonate cements were tested in the 1990s and found to

have different properties, including very high strengths and rates of biological

incorporation (Constantz et al.

1998

). Calcium carbonate cements were further

developed in France (Fontaine et al.

2001

) at the same time that General Motors was

developing the large-scale carbon mineralization processes, around 2002. Since

Norian, other examples of calcium carbonate cementing systems have been observed

in biological cement applications (Combes et al.

2006

). Coombs found that by

combining various metastable calcium carbonate, both ACCs and various crystalline

polymorphs such as vaterite and aragonite in combination, and optionally with

calcium phosphates as the Norian team had done, a workable cement resulted.

Coombs formulated a series of calcium carbonate cement with a variety of proper-

ties, including high strength and engineering porosity (Combes et al.

2006

).

In this work, various types of synthetic limestone are precipitated from aqueous

solution, namely two types of amorphous calcium carbonate, specifically strontium

containing and magnesium-stabilized amorphous carbonates are precipitated and

dried as powders. These amorphous carbonate powders were blended with a

secondary metastable calcium carbonate polymorph, namely vaterite, powder and

Search WWH ::

Custom Search