Environmental Engineering Reference

In-Depth Information

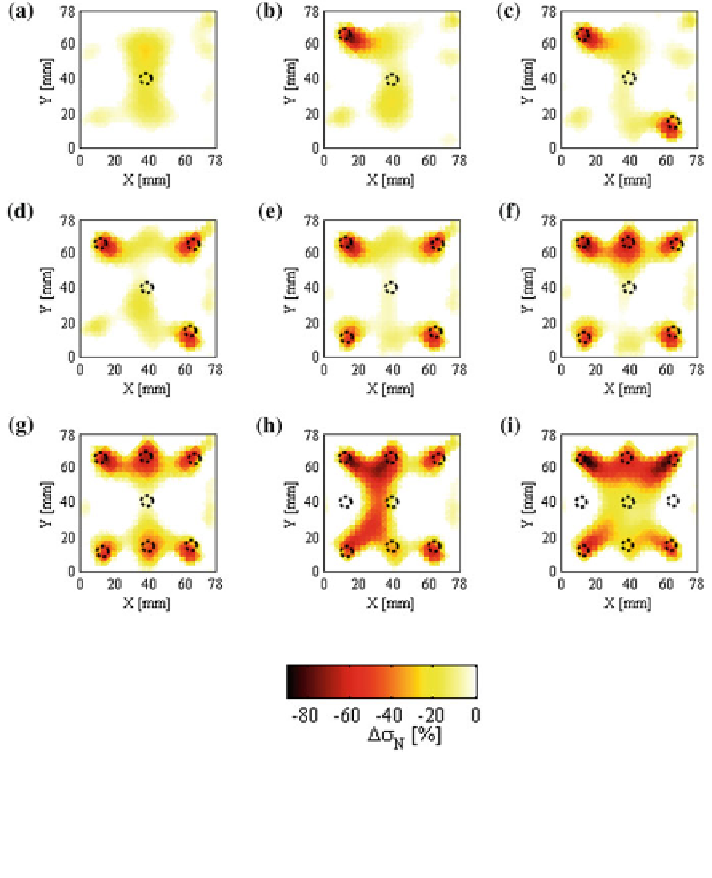

Fig. 11.9 The sensing skins and EIT algorithm are tested by verifying that this method could

detect the location of drilled holes in sensing skin-enhanced GFRP panels. Each EIT image is

obtained after a new hole is drilled in the a center, b upper-left, c lower-right, d upper-right,

e lower-left, f upper-center, g lower-center, h center-left, and i center-right of the composite

specimen (Loyola et al.

2013a

). (Images provided courtesy of Sage publications)

that EIT was able to resolve the severity and location of four different magnitude

impact damage sites (Loh et al.

2009

). The monitoring of spatial variations in pH

(i.e., as a precursor of corrosion) (Hou et al.

2007b

) and changes in film con-

ductivity due to corrosion/rust formation (Pyo et al.

2011

) were also validated.

More recently, an airbrushing technique for spray deposition of these CNT-

based sensing skins was developed for achieving rapid fabrication and field

applications (Mortensen et al.

2013

). In short, an ink solution was created by

dispersing multi-walled carbon nanotubes (MWNT) in poly(sodium 4-styrene-

sulfonate) (PSS) and the mixing it with a latex solution. The ink and latex mixture

Search WWH ::

Custom Search