Information Technology Reference

In-Depth Information

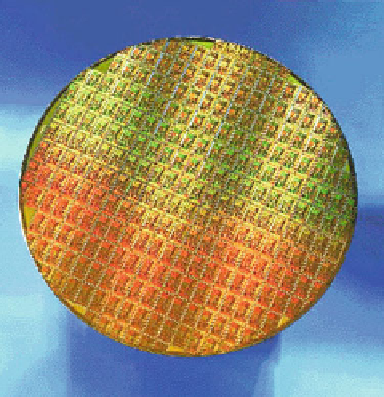

Fig. 2.12 Silicon wafer at

the stage of producing

integrated circuits

Today the semiconductor planar technology plays a central role in the produc-

tion of electronic circuits (chips) that are used in a large number of devices—

computers, control, and communication devices. It relies on a wide variety of

specific processes that differ in their physicochemical nature and the instrumen-

tation used. Typical for semiconductor technology are the extreme requirements

imposed on the purity of raw materials, handling medium (water, auxiliary mate-

rials), and the atmosphere of the production facilities. In chemical practice, both in

research and production, a substance is considered pure if the concentration of

impurities does not exceed 0.001 %. The number of atoms in 1 cm

3

of the semi-

conductor is 10

22

. Doping a semiconductor usually involves introducing 10

16

-10

19

dopant atoms per 1 cm

3

, i.e., 0.0001-0.1 %. This means that the concentration of

harmful impurities in silicon, which may affect its semiconducting properties, must

be below 0.00001 %.

The planar technology is characterized by a number of other important features.

However, since the main focus of this topic is on the interaction and mutual

influence of the computer technology and nanotechnology, we will confine consi-

deration to the most important problem in this context—the lithographic process

and the limits it imposes on miniaturization of electronic circuits.

2.3 Planar Semiconductor Technology:

Universal Acceptance and Limitations

Planar technology (see Fig.

2.13

) involves successive application on the surface of

the silicon substrate of thin layers of material which serves to form the individual

elements of the scheme, with subsequent processing of this layer.