Information Technology Reference

In-Depth Information

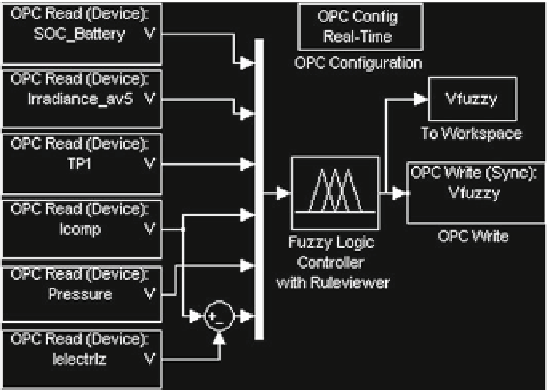

Fig. 12.6

Simulink block diagram of fuzzy control with OPC link scheme

for hydrogen production. The most favorable scenario takes place when there is

available capacity for hydrogen storage, the battery SOC is high, the irradiance is

high and themodule temperature is low. For the rest of situations, the controller output

adapts the hydrogen generation to both the energy availability and the technological

conditions.

It is worth to highlight that the compromise current is only used as threshold. To

this respect, if its value belongs to the subset

Low

, the output signal takes a small

value to reduce, or even stop, the hydrogen generation. The same behavior has been

defined if the bottle pressure is in the partition

High

of such a variable.

Figure

12.6

contains the block diagram of the real-time control system

implemented in Simulink. It consists of three subsystems: OPC Read blocks for

acquisition of input signals, fuzzy controller block for control signal generation and

OPC Write block for real-time writing on PLC memory. The communications para-

meters are defined with the OPC Configuration block, so Simulink acts as OPC

client.

12.4 WinCC, Simulink and PLC Integration

Figure

12.7

shows the sequence of operations from the reading of sensors connected

to the PLC until the generation of the output, Vfuzzy. The read values are stored

in data blocks in the PLC memory. The OPC Server of WinCC flexible Runtime

allows the access to these memory positions from Simulink by means of the OPC

Search WWH ::

Custom Search