Environmental Engineering Reference

In-Depth Information

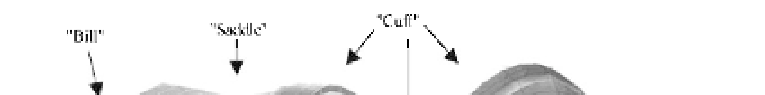

Fig. 8.64

(a) duckbill-shaped elastomer valve; (b) lip-shaped opening of duckbill valve; (c) definition diagram of

duckbill valve jet characteristics

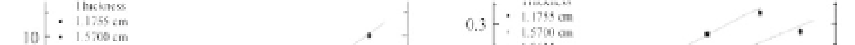

Fig. 8.65

Computed hydraulic characteristics of duckbill valve for different rubber thicknesses: a) pressure-discharge

variation and b) opening area as function of flow rate (after Lee et al, 2004)

With its unique hydraulic characteristics, a duckbill valve may always maintain sufficiently high jet

velocities (jet densimetric Froude number) and essentially permit flow only along one direction, which

could prevent salt-water, sediment and aquatic life from entering submarine outfalls even during low flow

periods. For example, at no flow condition, the flaps of the valve remain closed; as the discharge increases,

pressure is exerted on the flaps of the valve, and the valve opens more. Compared with traditional diffusers

with fixed diameters, experiments and turbulence modeling have shown that a duckbill valve may achieve

optimal mixing of the underwater effluent discharge with the receiving water (Lee et al., 1997; Kuang

and Lee, 2001).

Search WWH ::

Custom Search