Environmental Engineering Reference

In-Depth Information

4.3.3.9

Resistance and Drag Reduction in Pseudo-one-Phase Debris Flows

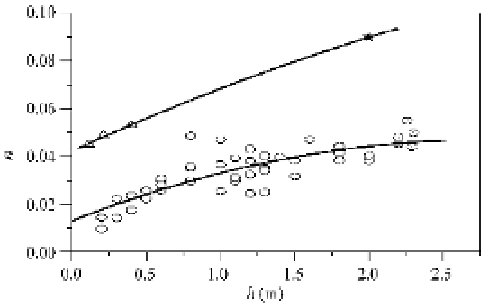

The resistance of a two-phase debris flow is much larger than for the flow of water. However, the resistance

of a pseudo-one-phase debris flow is sometimes lower than for the flow of water. Wang et al. (1999), assisted

by the Dongchuan Debris Flow Observation and Research Station, measured the roughness of clear water

flow in the Jiangjia Ravine, collected the resistance of pseudo-one-phase debris flows, and compared them,

as shown in Fig. 4.55. The resistance of debris flow is less than half that for clear water flow which means

that the velocity of debris flow in the gully is higher than 2 times that of clear water flow at the same flow

depths. This result implies a striking drag reduction in debris flow. There must be a special mechanism

resulting in the drag reduction.

Fig. 4.55

The Manning resistance coefficient,

n

, of clear water flows and pseudo-one-phase debris flows as a function

of flow depth,

h

, in the Jiangjia Ravine, Xiaojiang watershed on the Yunnan-Guizhou Plateau of China

Drag reduction is a focal point of research by scientists and hydraulic engineers, and sediment induced

drag reduction has been reported in the recent years. Chanson (1994) reported drag reduction resulting from

sediment and air bubbles. Wang et al. (1998) studied the resistance and drag reduction of hyperconcentrated

flow over rough boundaries and found that the drag reduction is due to the turbulence suppressing effect of

high concentrations and the smoothing of the boundary. Many parameters have been proposed to represent

resistance resulting from debris flow and none of them has been successfully applied to a specific flow.

If the pseudo-one-phase debris flow is homogenous and laminar, the resistance can be represented by

its rheological parameters such as viscosity and yield strength (Johnson and Rahn, 1970; Yano and Daido,

1965). Despite the much higher viscosity, the yield stress of debris flow means extremely higher resistance

rather than drag reduction. If the flow is turbulent, the resistance resulting from turbulent stress mostly

dominates the flow and there is no theoretical formula for the estimation of the resistance. The shape of

the channel and the bed form also contribute to the complexity of the problem. Hydraulic engineers have

applied the Manning roughness coefficient,

n

, to represent the resistance to the flow and experience has

been accumulated in the estimation of the roughness.

The drag reduction in debris flow is so obvious and is an important phenomenon receiving little

attention. The discharge of a debris flow gully, such as the Jiangjia and Dabaini gullies, is several times

higher than that of the Xiaojiang River into which they pour. Drag reduction is a cause of the extremely

high discharge.

The mechanism of the drag reduction is probably a result of the bed paving process. Figure 4.56 shows

a comparison of the bed surface before and after the bed paving process. The bed surface is obviously

smoother after the paving process. Another mechanism of drag reduction is due to air bubbles in the

debris mixture. Figure 4.57 shows the holes left by air bubbles in a debris flow deposit in a debris flow

gully in the Bailong River basin in Wudu County in Gansu Province.

Search WWH ::

Custom Search