Environmental Engineering Reference

In-Depth Information

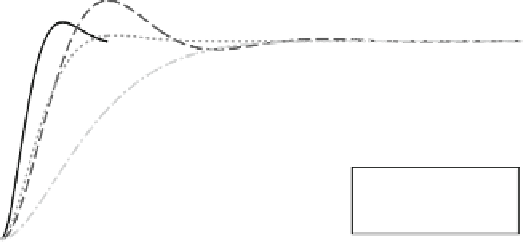

fault. Pump wear after approximately 20 years of operation might result in pres-

sure reduction to 75 % of the rated pressure, which is reflected by the faulty

natural frequency x

pw

¼

7

:

27 rad/s and a fault damping ratio of f

pw

¼

0

:

75.

Hydraulic leakage is another irreversible incipient fault, but is introduced

considerably faster than the pump wear. When this fault reaches a certain level,

system repair is necessary, and if the leakage is too fast, it will lead to a pressure

drop and the preventive procedure is deployed to shut down the turbine before the

blade is stuck in undesired position. The fast pressure drop is easy to detect and

requires immediate reaction, yet the slow hydraulic leakage reduces the dynamics

of the pitch system, and for a reduction of 50 % of the nominal pressure, the

natural frequency under this fault condition is reduced to x

hl

¼

3

:

42 rad/s and

the corresponding damping ratio is f

hl

¼

0

:

9. If the hydraulic pressure is too low,

the hydraulic system will not be able to move the blades which will cause the

actuator to stuck in its current position resulting in blade seize.

On the contrary to pump wear and hydraulic leakage, high air content in the oil

is an incipient reversible process, which means that the air content in the oil may

disappear without any necessary repair to the system. The nominal value of the air

content in the oil is 7 %, whereas the high air content in the oil corresponds to

15 %. The effect of such a fault is expressed by the new natural frequency x

ha

¼

5

:

73 rad/s and the damping ratio of f

ha

¼

0

:

45 (corresponding to the high air

content in the oil). The pitch system step response to each of the previously

illustrated faults that induce a change in performance is shown in Fig.

11.9

.

The performance degradation of the hydraulic system is simulated by updating

the natural frequency and damping ratio of the first blade according to a given rate.

This fault is introduced only to the first blade at time of fault TOF, and the natural

frequency and damping ratio are changed gradually from their nominal values

x

n

;

f to their new values x

n

ð

c

Þ

, f

ð

c

Þ

as in Eq. (

11.16

). The new values are reached

within duration T

i

.

1.4

1.2

1

0.8

0.6

0.4

No fault

High air content in oil

Pump wear

Pressure drop

0.2

0

0

0.5

1

1.5

2

2.5

3

Time [s]

Fig. 11.9

Step response for the normal and fault conditions of the pitch system