Environmental Engineering Reference

In-Depth Information

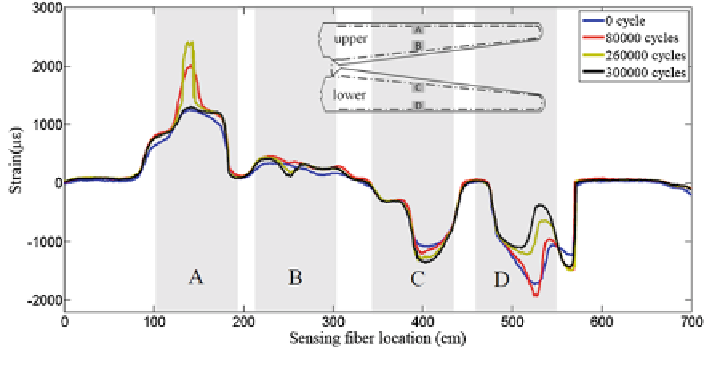

Fig. 9.21 The strain distributions at different fatigue cycle count obtained by Optical Fiber 2

tensile strain near the damaged region. As shown in the test results of strain

distributions at 260,000 cycles, the strain in the initial fatigue damage region

continuously increased. Especially near the leading edge side of the high strain

region on the upper surface (segment A of Optical Fiber 2), the strain was

extremely high, which indicated a further damage in this position. Between

260,000 and 300,000 cycles, adhesive joint failure between skins at the leading

edge was visually identified at 75 cm from the root, where was exactly the

extremely high strain position in segment A of Optical Fiber 2. Adhesive joint

failure broke the structure integrity and released the stress near the damage region,

which led to a sudden decrease of the stain near adhesive joint location. As shown

in the test results of strain distributions at 300,000 cycles, the strain near the failed

adhesive joint significantly decreased (segment A of Optical Fiber 2), which show

the effectiveness of severe fatigue damage detection in DPP-BOTDA system. As

the crack of adhesive joint failure progressed in length, the blade lost its structural

integrity and failed at about 310,000 cycles. The strain distributions obtained by

the DPP-BOTDA system at different fatigue cycle count validated the effective-

ness of the developed system in damage detection and distributed sensing.

The Brillouin gain spectra (BGS) is the foundation of all the Brillouin sensors.

According to the principle of Brillouin scattering-based strain and temperature

measurement, only the Brillouin frequency shift determines the final measurement

results of strain and temperature. But other parameters of the BGS in the sensing

fiber, like width, amplitude, even the shape of the BGS, contain more information

about the local strain field, as these parameters are influenced by the local strain

gradient and the nonuniformity of the strain distribution. Then, these parameters

also can be used to detect and locate damage [

54

,

55

].

The normalized fitted BGS, obtained by the DPP-BOTDA system at different

fatigue cycle count, along the leading edge are shown in Fig.

9.22

. In undamaged

state (0 cycle), the test results reveal that BGS along the leading edge have a similar