Environmental Engineering Reference

In-Depth Information

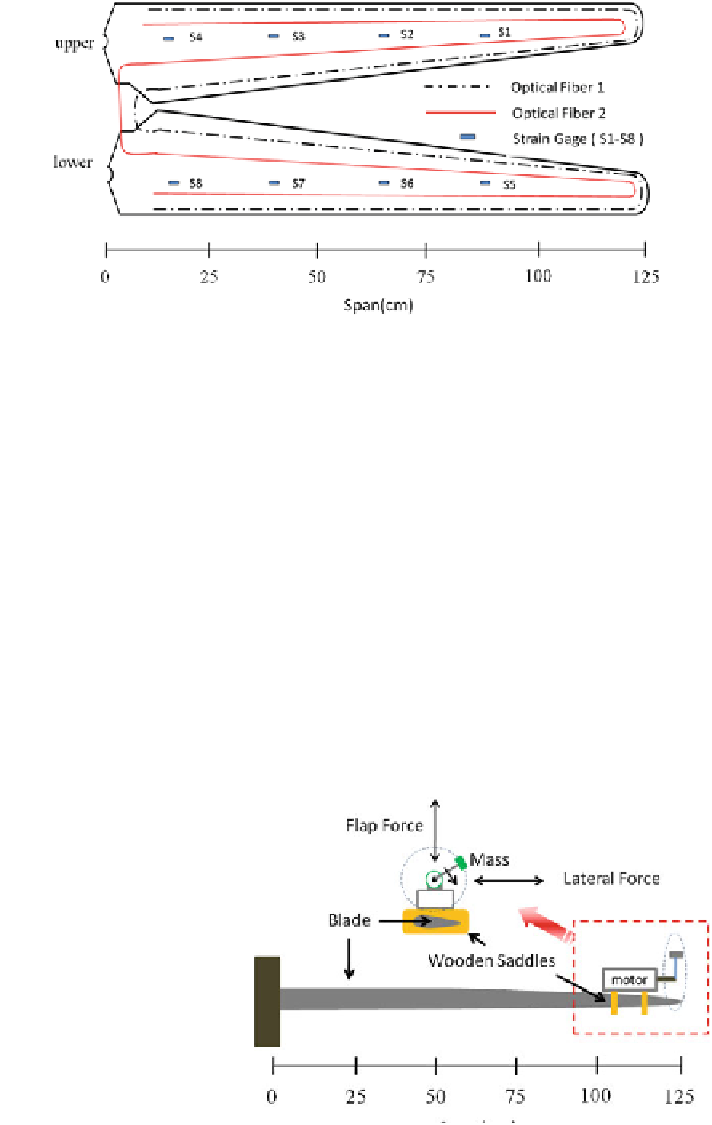

Fig. 9.15 Layout of optic fiber sensors and strain gauges

blade along with optical fiber to validate the measurement accuracy of the dis-

tributed sensing and continuously monitor the condition of the blade. Hence, the

measurement taken is stable and reliable during the blade fatigue test process.

9.3.2.2 Summary of Test Procedure

Figure

9.16

shows the fatigue test loading system for wind turbine blade based on

single-axis resonance method [

53

]. An electric motor, connected with a 1 kg mass,

was mounted approximately at 115 cm from the blade root using wooden saddles.

The motor was driven to excite the first flap frequency and induce a cyclic load in

the blade. The loading cycle frequency is about 2.6 c/s. The initial strain ampli-

tudes of the fatigue loading along the spanwise axis on both side of the blade are

shown in Fig.

9.17

.

Fig. 9.16 Schematic of the

fatigue loading system