Environmental Engineering Reference

In-Depth Information

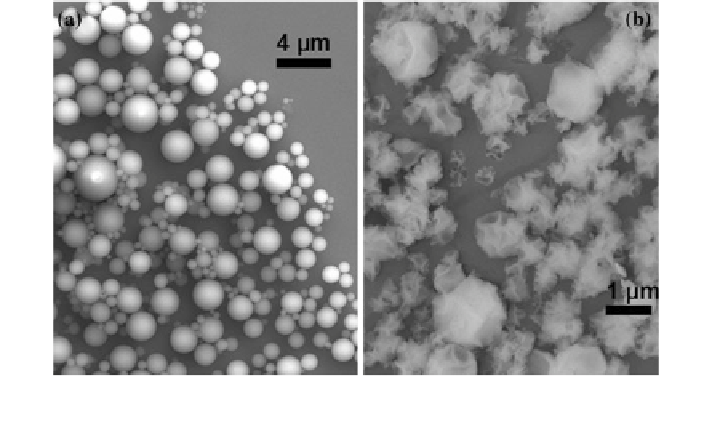

Fig. 5 SEM image of a as-synthesized microcapsules of NPG in silica shell, and b wrinkled

silica shell after removal of NPG [

32

]

consumed by the hydrolysis of TEOS. These microcapsules are dried in a vacuum

oven to remove the residual ethanol.

The SEM image of the NPG-silica microcapsules is shown in Fig.

5

a. It can be

seen that these microcapsules are spherical in shape with smooth surface. The

diameter of these microcapsules is in the range of 0.2-4 lm. The NPG micro-

capsules have a relatively wider size distribution due to the large viscosity of the

aqueous phase, NPG solution [

33

]. After removing NPG from the microcapsule,

the silica shell collapses without rupture on the shell, as shown in Fig.

5

b. The

flexibility of the silica shell is due to its thin thickness, about 30 nm.

3.5 Phase Change Behavior of Heat Transfer Fluids

with Microcapsules

The effective heat capacity of heat transfer fluids can be enhanced by dispersing

appropriate PCM particles into them. Figure

6

shows the DSC curves of the PAO

dispersion with 20 wt% of paraffin microcapsules. PAO has been widely used as

dielectric heat transfer fluids and lubricants. It remains oily in a wide temperature

range due to the flexible alkyl branching groups on the C-C backbone chain, but it

has relatively poor thermal properties. The overall latent heat of the fluid is

measured as 23.5 J/g. The effective specific heat capacity is about 3.37 J/g k when

the temperature difference between the heat transfer surface and the fluid is

assumed to be 20 C. This value indicates a more than 50 % increase in effective

heat

capacity

in

the

microcapsule

dispersions,

compared

to

the

pure

PAO.

Search WWH ::

Custom Search