Environmental Engineering Reference

In-Depth Information

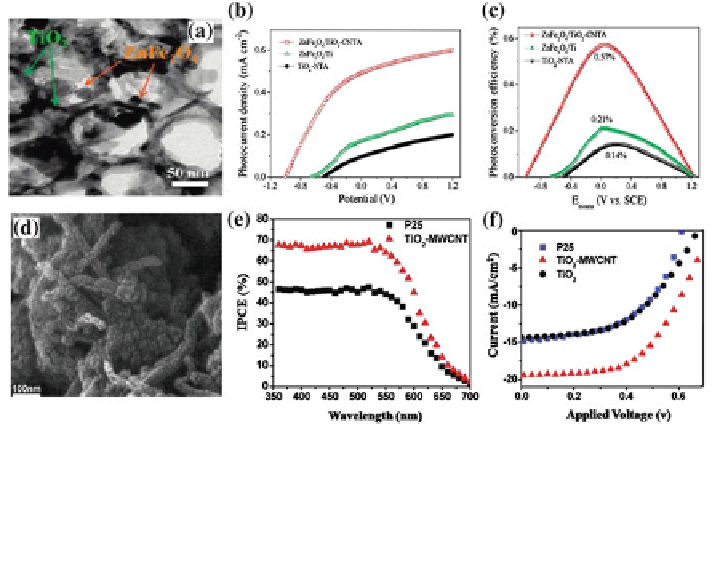

Fig. 16 SEM images of ZnFe

2

O

4

/TiO

2

nanotubes (a) and TiO

2

MWCNT nanocomposite (d).

b Variation of the photocurrent density versus bias potential (versus SCE) and c Photoconversion

efficiency as a function of the applied potential (versus SCE) based on (a). IPCE curves (e) and

current-voltage characteristics (f) of DSSCs based on TiO

2

MWCNT nanocomposite (c).

(Reprinted with permission from Ref. a-c [

365

], d-f [

366

]. Copyright American Chemical

Society)

Several synthetic strategies have been designed to fabricate graphene-TiO

2

photocatalysts. In the first method, well-defined TiO

2

structures are deposited on

the surface of graphene oxide (GO) under vigorous stirring or ultrasonic agitation

[

368

-

370

]. The site-specific oxygenated groups on GO favor a uniform distribu-

tion of TiO

2

across the surface. Graphene-TiO

2

photocatalysts are obtained after

the reduction of GO in the composite [

371

,

372

]. Yang et al. packed TiO

2

and

graphene nanosheets into a 2D unit (TiO

2

/graphene) that is structurally similar to a

thylakoid in the chloroplast of photosynthetic plants. In this 2D unit, TiO

2

per-

forms as a photo-electric conversion center to absorb light and excite the electrons,

while graphene is like the cytochrome b6f complex capturing electrons and

transporting them out of the circuit. Such a novel structure was formed by stacking

TiO

2

nanosheets and GO nanosheets using a layer-by-layer (LBL) assembly

technique in the presence of charged poly(diallyldimethylammonium chloride)

(PDDA) which supplied the counter-ions. GO was reduced to graphene by

hydrazine and annealed under argon flow at 400 C and the PDDA was then

removed by calcining at 450 C in air. The graphene-TiO

2

stacking film can

produce an anodic current 20 times larger than pure TiO

2

stacking films. Inter-

estingly, the current further increased with thicker films [

373

]. Another significant

example, graphene-wrapped anatase TiO

2

nanoparticles (Fig.

17

a) with a signifi-

cant reduction in the band gap (2.80 eV, Fig.

17

b) were prepared by wrapping

Search WWH ::

Custom Search