Environmental Engineering Reference

In-Depth Information

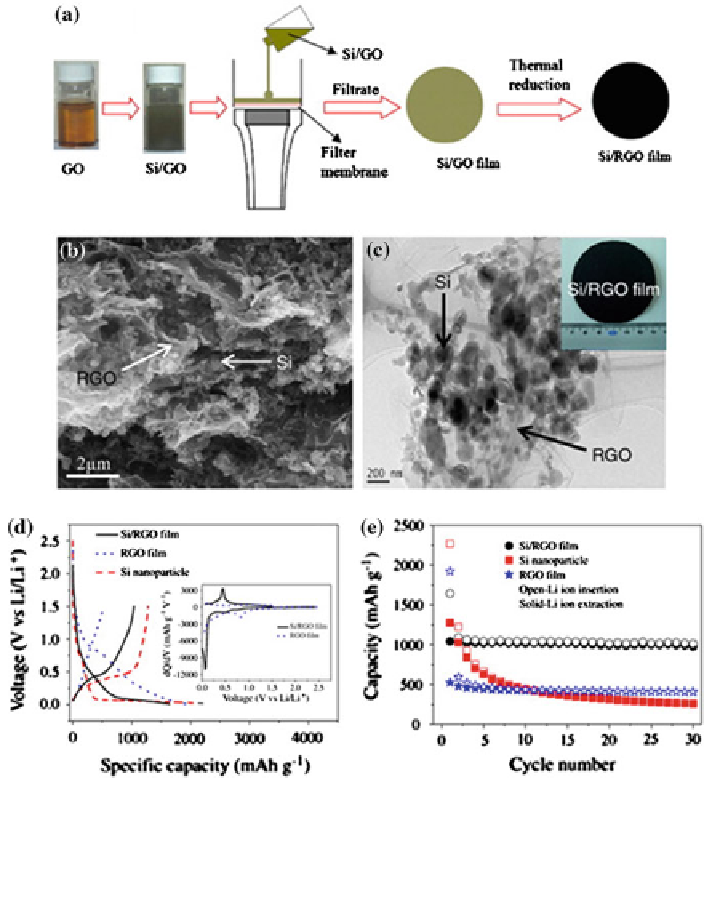

Fig. 13 a Schematic diagram of the fabrication of Si/graphene film. b SEM and c TEM images

of the Si/graphene film. d The first charge/discharge curves of Si/graphene film, graphene film

and Si nanoparticles at a current density of 50 mA g

-1

. e Cycling stabilities of Si/graphene film,

graphene film and Si nanoparticle electrodes at a current density of 50 mA g

-1

. Reprinted with

permission from [

72

]. Copyright (2011)

Composite films were assembled LBL by 20-layer films (10 layers graphene, 10

layers MnO

2

nanotube, and the weight ratio of graphene/MnO

2

nanotube is 1:1),

with each layer prepared by filtration of graphene or MnO

2

nanotube dispersion.

By this method, the number of layers and composition of each were properly

controlled. Each thin layer of graphene provides not only conductive pathways to

accelerating the electrochemical reaction, but also buffer layers for strain release

during lithium insertion/extraction in MnO

2

(Fig.

14

b). The graphene-MnO

2

nanotube films as anode present excellent cycle and rate capabilities with a

Search WWH ::

Custom Search