Environmental Engineering Reference

In-Depth Information

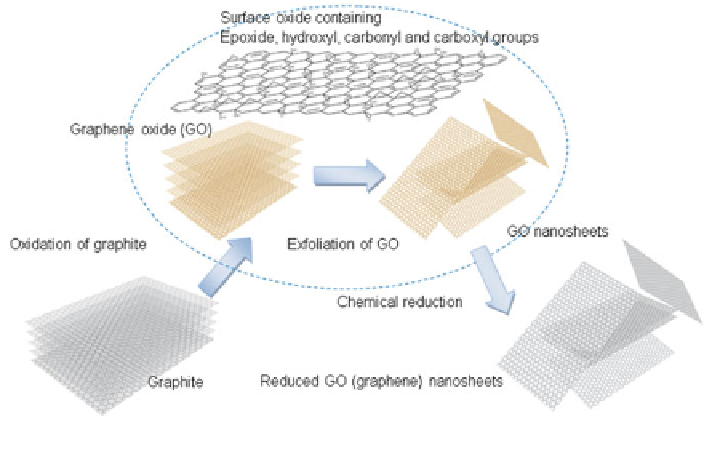

Fig. 2

Illustration of the production of graphene from the graphite oxidation route

apparatus, and accurate control over operating, which hindered the large-scale

manufacturing of graphene. Instead of the high-cost methods for generating

graphene, the production of graphene sheets by oxidative exfoliation of graphite

and subsequent reduction (Fig.

2

) can offer the high-volume production of RGO

(graphene) [

42

]. Furthermore, functionalized graphene materials are highly dis-

persible in a wide range of solvents, make it easy processable and can be

assembled into various desired macroscopic structures or incorporated with other

nanomaterials into functional composites [

32

,

41

,

44

,

47

]. Although graphene

materials produced by the chemical route possess such advantages, they are still

far inferior to products prepared by mechanical cleavage or CVD due to the high

density of plane defect, which may be undesirable for some technological appli-

cations such as in electronics. However, the defects induced by the chemical

process can provide chemical active sites on the graphene surface, which may

enhance the performance of graphene in the application where high chemical

activity is required, combined with its low cost and large yield, the chemical

reduction generated graphene is especially suitable in the area of energy storage,

catalyst, and chemical sensors, etc.

Recently, Ruoff and Wallace et al. demonstrated that vacuum filtration of the

as-prepared GO or graphene dispersion can result in the formation of free-standing

paper-like materials exhibiting smooth surfaces, which can be called graphene

paper (GO paper) or film [

44

,

48

]. A typical graphene paper possesses a layered

structure through the entire cross section (SEM image in Fig.

3

a) [

49

]. And in X-

ray diffraction pattern, the graphene paper obtained by vacuum filtration displayed

a weak, broad diffraction peak of at about 2h = 23 (Fig.

3

b), which corresponds

to a layer-layer distance (d-spacing) of 0.379 nm, such value is a little larger than

Search WWH ::

Custom Search