Environmental Engineering Reference

In-Depth Information

Table 1 Variation of proton conductivity, domain size and yield strength with s-MWCNT

composition and water content

Membrane composite

Proton

conductivity

(S cm

-1

)

Hydrophilic domain

size (nm)

Water

content (%)

Yield strength

(MPa)

Nafion 115

0.028

48

29.2

2.68

Recast Nafion

0.020

51

42.3

2.40

Naf-s-MWCNT 0.01 %

0.029

54

39.7

2.50

Naf-s-MWCNT 0.05 %

0.036

72

33.4

2.62

Naf-s-MWCNT 0.1 %

0.032

70

30.4

2.67

Naf-s-MWCNT 0.5 %

0.031

67

28.1

3.10

Naf-s-MWCNT 1 %

0.030

35

27.2

4.30

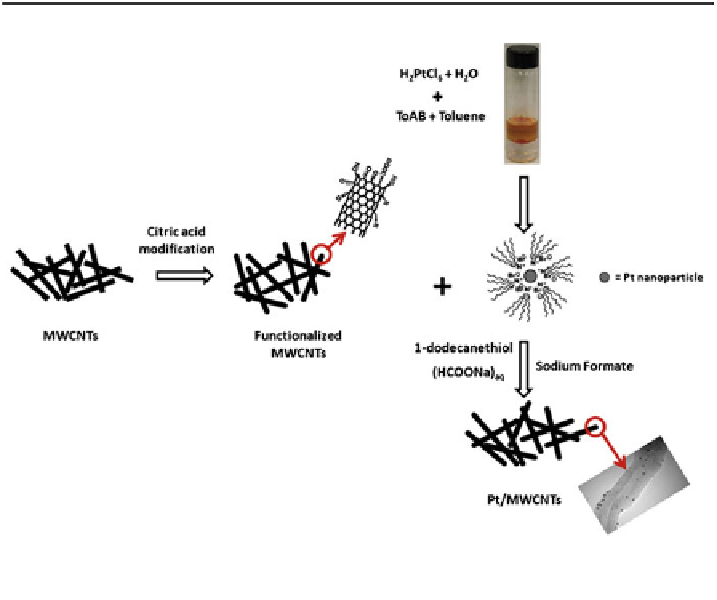

Fig. 4 Scheme for the surface modification of MWCNTs and Pt nanoparticles deposition

(adapted from Ref. [

66

] with permission from Elsevier publishing company)

chemical modification route [

66

]. By this method Pt nanoparticles of 1-3 nm are

stabilized at the same time maintaining a uniform Pt distribution due to the

anchoring groups present on the CNT surface (Fig.

4

). Interestingly, fuel cell

polarization plot with this catalyst shows a power density of 1,110 mW cm

-2

against 800 mW cm

-2

(5 cm

2

area) observed for a commercial catalyst. Further,

the activation loss observed at 50 mA cm

-2

is only 50 mV from the OCV for this

surface-modified process compared to that of 150 mV for unmodified CNTs.

However, with the carbon black it is much higher, which signifies the more effi-

cient use of CNTs in the catalyst layer of PEMFCs.

Search WWH ::

Custom Search