Environmental Engineering Reference

In-Depth Information

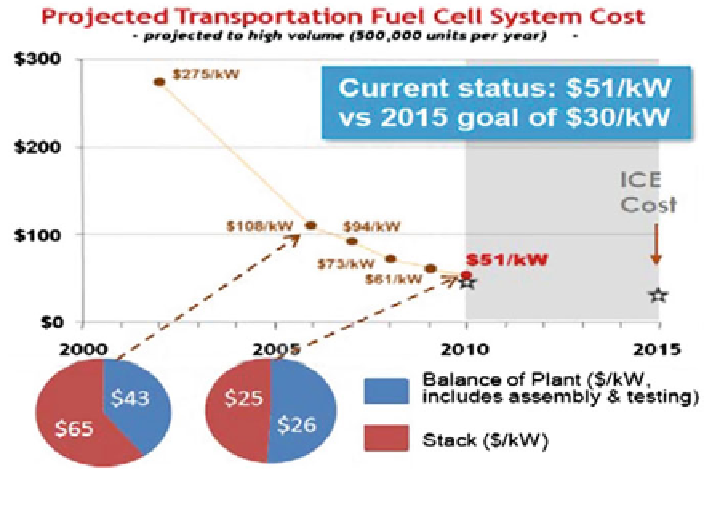

Fig. 1

DOE projected transportation fuel cell system cost (adapted from Ref. [

26

])

normally in the temperature range of 30-100 C under humidified environment

although PEMs that can operate up to 200 C are also available. The easy start-up

and flexible design has attracted interests in both stationary and portable appli-

cations [

4

,

18

,

19

]. In fact, it represents one potential case for reducing the green

house gas emission from a renewable energy point of view especially if hydrogen

is produced by solar technologies without any carbon footprint [

20

]. PEMFCs also

have higher practical efficiencies over commercial engines especially if combined

heat-power generation (cogent) is targeted [

21

].

A state-of-the-art PEMFC accordingly has five critical components: (i) Pt

electrocatalyst, (ii) catalyst support carbon, (iii) gas diffusion layer (GDL) or

backing layer, (iv) bipolar plates and (v) polymer electrolyte membranes. For the

successful operation of PEMFCs, the reactant H

2

and O

2

must reach the catalyst

site where the electrochemical reactions take place and the product water has to be

expelled from the catalyst site to prevent water clogging and better access of

reactant gases to the electrocatalyst. Similarly, the generated protons at the

electocatalyst sites must reach the cathode through PEM while the electrons need

to reach the cathode through an external circuit, where it does the useful work, to

react with oxygen and protons to form water. Hence, the effective formation of

triple-phase

boundary

(TPB)

(reactant

gases,

electrocatalyst

and

electrolyte

membrane) is an important criterion for successful PEMFC operation.

Despite many advantages, PEMFCs still have many challenges owing to the

availability of critical materials and processes to effectively address the lack of

commercialization aspects [

22

,

23

]. For example, the use of Pt as electrocatalyst,

Search WWH ::

Custom Search