Environmental Engineering Reference

In-Depth Information

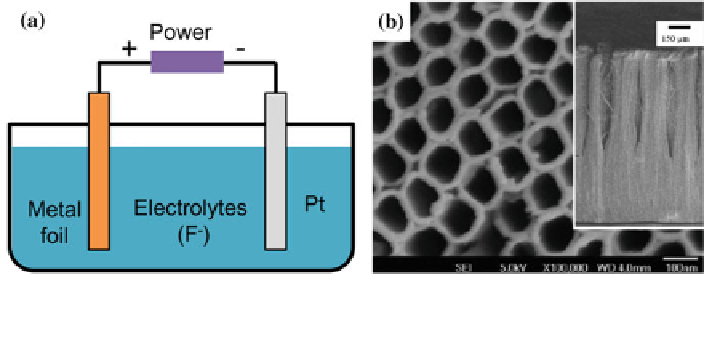

Fig. 5 a A schematic diagram of a two-electrode electrochemical cell for anodization. b SEM

images of TiO

2

NTAs prepared by potentiostatic anodization of Ti foils in an ethylene glycol

electrolyte containing NH

4

F and H

2

O. Reproduced with permission from [

70

]

obtained by anodic oxidization in aqueous or organic electrolytes containing

fluoride ions. For example, Cai et al. investigated the effect of electrolyte com-

position on the fabrication of TiO

2

NTAs. By adjusting the pH of electrolyte

using different additives, TiO

2

NTAs with different lengths ranging from 300 nm

to 6.4 lm were formed in an aqueous electrolyte containing potassium fluoride

[

4

]. Schmuki et al. synthesized TiO

2

NTAs with a length of up to 4 lmina

neutral fluoride solution containing phosphate [

20

]. Due to the high chemical

dissolution rate in an aqueous solution containing fluoride ions, the length of the

prepared TiO

2

NTAs was short. In comparison to aqueous electrolytes, much

longer TiO

2

NTAs can be formed in polar organic electrolytes due to low

chemical dissolution rate resulting from low water content. The most commonly

used organic electrolyte is ethylene glycol [

77

], glycol [

57

], acetic acid [

91

],

formamide (FA) [

81

], and dimethylsulfoxide (DMSO) [

116

]. By using organic

electrolyte, the length of TiO

2

NTAs could be extended to up to 100 lm under

the proper anodization conditions in organic electrolyte [

70

,

71

]. Grimes and co-

workers have widely explored the organic electrolytes in preparing the TiO

2

NTAs and have made significant progress. Recently, they prepared highly

ordered TiO

2

NTAs of over 1,000 lm in length and aspect ratio about 10,000 by

potentiostatic anodization of Ti foils in an ethylene glycol electrolyte containing

NH

4

F and H

2

O[

70

]. The length and the wall thickness of the TiO

2

NTAs were

readily controlled by adjusting the electrochemical parameters such as the

anodization duration, the composition and temperature of the electrolyte, and the

anodization voltage. Besides TO

2

nanotube, other metal oxide nanotube and

nanoporous nanostructures have developed such as Fe

2

O

3

[

39

,

109

], WO

3

[

118

,

120

], Nb

2

O

5

[

19

], and Ta

2

O

5

[

15

,

40

] via the same electrochemical anodization

method. These research works have demonstrated electrochemical anodization to

be

an

effective

approach

to

fabricate

high

surface

area

metal

oxide

nanostructures.

Search WWH ::

Custom Search