Environmental Engineering Reference

In-Depth Information

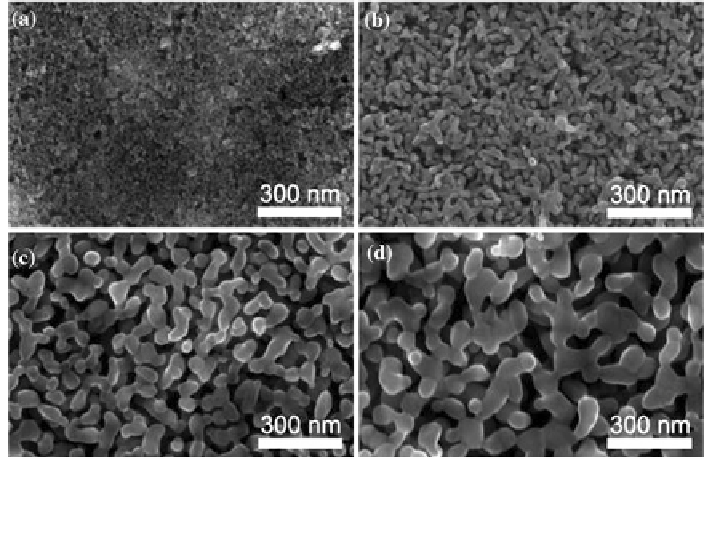

Fig. 4 2 Scanning electron micrographs of mesoporous hematite films prepared on SiO

2

/F:SnO

2

substrates after different heat treatments: a As deposited with porogen b After 10 h at 400 C,

and c After 20 min at 700 C and d 800 C. Reproduced with permission from [

83

]

from aqueous solutions at room temperature [

58

]. The multifaced 3D structure act

as a light-scattering layer, which can significantly improves the photocurrent by

reducing the loss via surface light reflection.

2.4 Electrochemical Anodization Method

Electrochemical anodization of metal foils is a simple and convenient method for

creating ordered and self-oriented porous metal oxide nanostructures perpendic-

ular to the substrate with controllable pore size and length, especially for nanotube

arrays (NTAs) [

21

,

60

,

70

,

71

,

104

]. Anodization of metal foils is usually con-

ducted in a conventional two-electrode electrochemical cell with a platinum foil as

cathode at a constant potential. A schematic diagram for the anodization of metal

foils is illustrated in Fig.

5

.

A type example is electrochemical anodization of Ti foil to prepare vertically

and highly ordered TiO

2

NTAs. In 2001, Grimes and co-workers first reported the

formation of TiO

2

NTAs via electrochemical anodization of Ti foil in a hydro-

fluoric electrolyte [

21

]. Further studies focused on the precise control the mor-

phology of TiO

2

NTAs such as pore size, length, and wall thickness. Electrolyte

composition plays a critical role in determining the morphology and structure of

TiO

2

NTAs. So far, TiO

2

NTAs with various diameter and length are easily

Search WWH ::

Custom Search