Environmental Engineering Reference

In-Depth Information

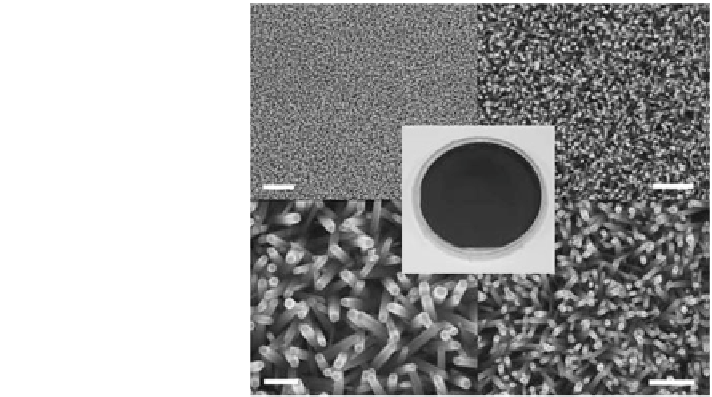

Fig. 3 ZnO nanowire array

on a 4-inch (ca. 10 cm)

silicon wafer. At the center is

a photograph of a coated

wafer, surrounded by SEM

images of the array at

different locations and

magnifications. These images

are representative of the

entire surface. Scale bars,

clockwise from upper left 2,

1 mm. 500 and 200 nm.

Reproduced with permission

from [

24

]

the film. Mesoporous films heat-treated below 300 C appeared yellow, compared

to the red films obtained after annealing at higher temperatures. Prochazka et al.

synthesized the exceptionally dense TiO

2

films via dip-coating from a sol con-

taining poly(hexafluorobutyl methacrylate) as the structure-directing agent [

72

].

The TiO

2

films can be deposited on glass, F-doped SnO

2

, and crystalline silicon

(111) faces. Noriyuki et al. fabricated ZnO/Zn

0.85

Mg

0.15

O heterostructure thin

films by sol-gel spin-coating method on sapphire (0001) substrate [

66

]. The

bottom ZnO layer was prepared from zinc acetate dissolved in 2-methoxyethanol.

And, monoethanolamine was added to the solution until reaching the same molar

ratio with Zn ions. Its solution was deposited onto sapphire substrate by spin-

coating process, and then annealed in air at 280 C for 1 min to remove the

solvent. Likewise, Elfanaoui et al. used a very simple and low-cost sol-gel syn-

thesis technique to prepare granular TiO

2

film [

12

]. Thin films of TiO

2

were

deposited by the method of spin coating in air at room temperature, on corning

glass as substrate. The films were dried at 100 C for 1 h and annealed at 300, 350,

and 400 C in air during 1 h. They investigated the effect of the number of

coatings and the annealing temperature on the films as well.

In comparison to sol-gel spin-coating techniques, doctor-blading of thin films is

an even more simple and convenient method for creating ordered and mesoporous

nanostructures [

1

,

34

,

75

,

83

]. Films that are 10 lm thick can be fabricated with

relative ease using this method. For example, Kabre et al. prepared a Tin-doped

TiO

2

photoanodes with a thickness of 2 mm and a resistance of 8 X/sq on a

2.5 9 2.5 cm of FTO glass [

34

]. A TiO

2

slurry was prepared by grinding 2 g of

Degussa P25 TiO

2

powder in 3 mL of 10 % acetic acid for 30 min, followed by

addition of 1 drop of an aqueous 10 % Triton-X solution. The slurry was then

deposited on the conductive side of the glass plate using the doctor blade technique

with a mask made of 3 M tape applied to three sides of the plate. After air drying

Search WWH ::

Custom Search