Environmental Engineering Reference

In-Depth Information

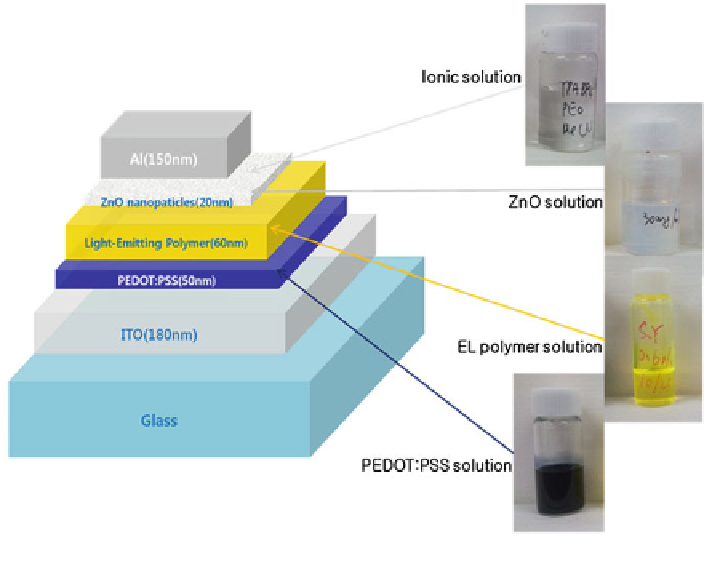

Fig. 12

Illustration of the multilayer structure and the solutions of the functional layers

brittleness. Moreover, the flexible ITO sputtered on PET substrate has less

transmittance and conductivity than that of the ITO-glass. There are many can-

didates for the alternative transparent electrodes such as metal mesh, silver

nanowire [

11

], graphene [

12

], carbon nanotubes [

13

], and conducting polymer

[

14

]. The conducting polymer of PEDOT:PSS fabricated by roll-to-roll coating

offers satisfactory optical transparency and electrical conductivity (Fig.

13

)as

polymer anode. For example, a 200 nm thick polymer anode (PEDOT:PSS, H.C.

Stock PH1000) can be coated by roll-to-roll blade-slit coating method over large

substrate at one time without wasting of the solution as shown in Fig.

14

.In

comparison, spin coating method requires three time coatings and wasting lots of

solutions to cast the same 200 nm thick polymer anode. The sheet resistance of the

polymer anode made by roll-to-roll coating is around 40 X/sq, when the thickness

is 250 nm. The transmittance including PET substrate of the polymer anode is

74 % at 550 nm wavelength. For a thinner, 120 nm thick polymer anode, the sheet

resistance is 110 X/sq and the transmittance is around 85 %.

Search WWH ::

Custom Search