Environmental Engineering Reference

In-Depth Information

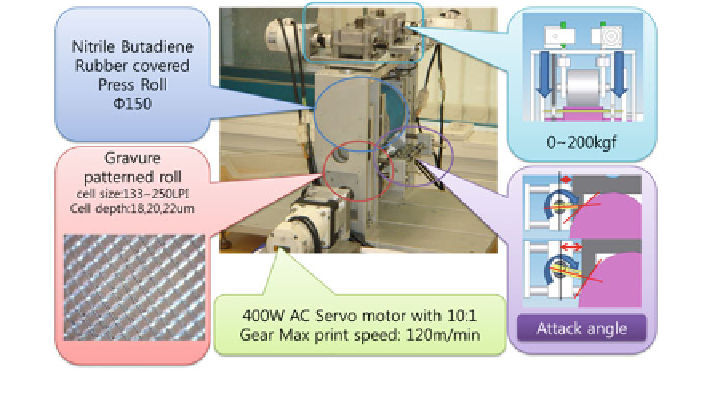

Fig. 8

The gravure coating system and its coating parts

Uniform film is important to ensure proper device function. Example, the streak

patterns of the emissive material shown in Fig.

9

can cause electrical shorting

problems under the bias voltage. This unwanted streak pattern can be controlled by

adjusting the printing speed and ink viscosity. The viscosity of the solution can be

reduced by diluting the solution as discussed earlier for the emissive polymer. For

another example, the commonly used conductive polymer PEDOT:PSS solution is

also difficult to form a uniform film on the polymer substrate as shown in Fig.

10

.

In this case, since the solution is water-born and hydrophilic solution, it is difficult

to coat uniformly. The irregular pattern of the PEDOT:PSS layer can be controlled

by adding isopropyl alcohol (IPA) solution to reduce viscosity. Dilution with IPA

has better effect than that of adding a surfactant. However, it is hard to obtain an

appropriate film thickness by one time coating using a lower concentration solu-

tion. Therefore, in the case of using the viscous solution, the film quality is

sensitive to the coating instability caused by ink transfer in the contact coating

method. Due to the basic problems of the contact coating process, non-contact

coating methods will be introduced. Slot-die coating as a typical non-contact

coating is a good manufacturing tool for the large scale solar cells.

2 Characteristics of Roll-to-Roll Coated Functional Layers

Toward the Large Scale Devices

This section describes the roll-to-roll/blade-coating process with applications in

large area OPV and OLED devices. We discuss the requirements of the functional

layers (e.g., transparent electrode, hole extraction layer, charge separation layer,

Search WWH ::

Custom Search