Environmental Engineering Reference

In-Depth Information

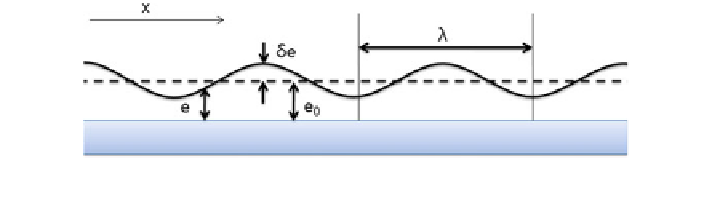

Fig. 7

The ideal modeling of the coating ripples of the wet film solution

The film thickness variation, expressed as d

;

will be reduced by the self-leveling

flow. We estimate the leveling time s. First the fluid speed (v) can be deduced from

the 1-dimensional Navier-Stokes equation. Then the flow rate Q can be deduced

from Young-Laplace equation:

2

v

oz

2

¼ 0

o

p

ox

þ

l

o

ð

10

Þ

Q

e

0

l

rq

3

de sin

ð

qx

Þ

ð

11

Þ

Considering the volume conservation,

o

Q

ox

¼

l

o

e

ð

12

Þ

ot

dde

dt

¼

de

ð

13

Þ

s

Solving the differential equation yields the leveling time as follows:

s ¼

lk

4

re

0

ð

14

Þ

If leveling time is smaller than evaporation time, the pattern will disappear due to

the leveling flow. However, if the leveling time is too long or evaporation time too

fast, the irregular pattern will remain. The leveling time depends on the viscosity

and surface tension of the solution. For instance, when the viscosity of the given

polymer solution is 100 mPa s, the surface tension is 25 m N/m, the characteristic

pitch of the stripes is 500 lm, the wet film thickness is 10 lm, and the leveling

time will be 250 s. To remove the irregular patterns, the solvent having higher

boiling temperature should be considered. By choosing a solvent that can evap-

orate slowly beyond the leveling time, flat and uniform films can be produced

(Fig.

8

).

Search WWH ::

Custom Search