Environmental Engineering Reference

In-Depth Information

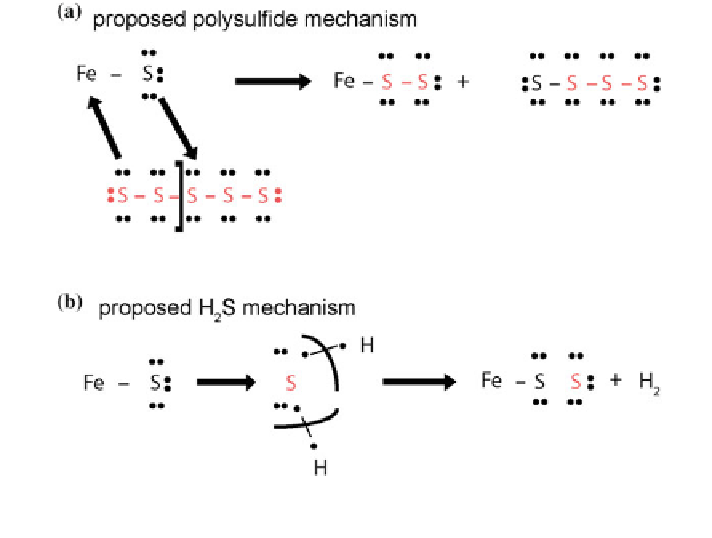

Fig. 2 a Proposed mechanisms of pyrite formation through a FeS intermediate. Reprinted with

permission from [

36

]

2.2 Hydrothermal Synthesis of Nano Pyrite

Hydrothermal methods have been used extensively in nanocrystal synthesis in the

past [

3

,

25

,

43

]. This method makes use of a stainless steel digestion bomb that is

typically Teflon lined. The buildup of pressure in the container allows for lower

temperature to be used instead of high temperature ambient pressure synthesis; care

must be used during use due to this pressure buildup, which is why these systems

have earned the nickname ''bomb.'' The use of a single precursor is usually used,

and through the decomposition of the molecule produces the reactive species.

Greater control of the system is achieved due to lack of variables such as injection

rate and injection temperature. Having a single precursor though limits you to only

a few precursors and are expensive. Another drawback of these systems is the time

required to carry out the reaction (*24 h) and the lack of the ability to take timed

aliquots of the sample during synthesis to study reaction progression. Even with

these drawbacks, it is still used for its simplicity and control.

One of the first reports of utilizing hydrothermal synthesis methods come from

Chen et al. [

43

]. In this chapter, an iron Diethyldithiocarbamate (Fe(S

2

CNEt

2

)

3

)

complex was utilized for the single precursor, and upon completing the reaction

cubic FeS

2

crystallites with *500 nm edge lengths were obtained. It was shown

that a minimum temperature of 180 C was necessary to achieve pure phase pyrite,

and that lower temperatures produced marcasite impurities. These crystallites

Search WWH ::

Custom Search