Environmental Engineering Reference

In-Depth Information

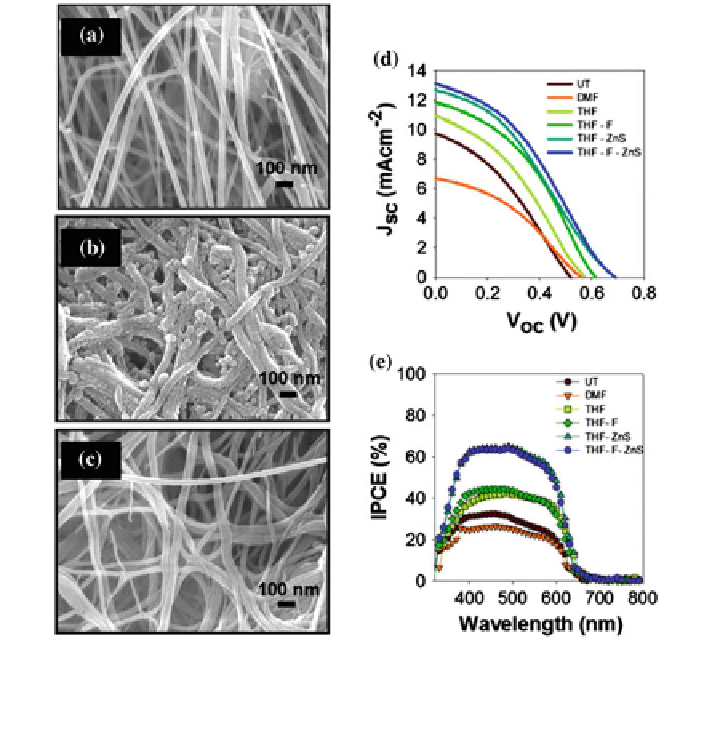

Fig. 9 SEM images of (a) untreated (b) DMF treated and (c) THF vapor-treated TiO

2

fibers;

d current-voltage (J-V) measurements and (f) IPCE spectra of QDSSCs using different surface

treated TiO

2

fibers electrodes. The electrode thickness is 2.4 lm. (Sudhagar et al. [

63

] reprint

permission from RSC publishers)

photocurrent. The observed higher performance in THF vapor-treated cells may

attribute to the improved physical adhesion of fibers with the TCO substrate. The

recombination parameters of this system have been studied and found that

chemical vapor treatment offer high charge recombination resistance to the elec-

trodes. Interestingly, these TiO

2

fibrous membranes afford high feasibility in

altering their Fermi level under post-doping process. Under the post-doping of

fluorine ion (in Fig.

9

d, THF+F) results upward Fermi level shift in TiO

2

con-

duction band. This Fermi level upward shift promotes the V

oc

as well as fill factor

(FF) of the device. We found that the combined pretreatment (THF) and post-

treatment (F ion doping and ZnS QDs decoration on CdS/CdSe QDs) the 3-D TiO

2

fibrous photoanode yielded a device performance of 3.2 % with a remarkable

V

oc

= 0.69 V compared with most of the reports existing in the literature.

Yet another attempt on improving the electrical contact between fibrous elec-

trode with TCO substrates has been demonstrated by Samadpour et al. [

107

].

Search WWH ::

Custom Search