Environmental Engineering Reference

In-Depth Information

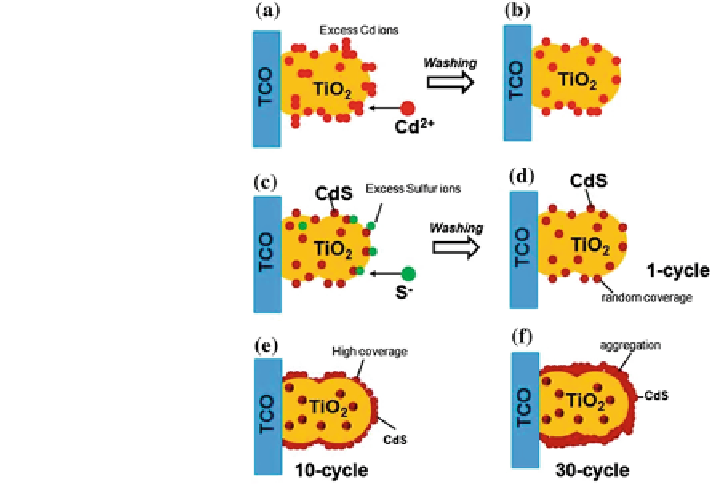

Fig. 3 Schematic illustration

of SILAR process

(a) Adsorption of cationic

ions (Cd

2+

)(b) rinsing (I)

removes excess,

nonspecifically adsorbed

Cd

2+

(c) reaction of anionic

(S

-

) with preadsorbed Cd

2+

ions to form CdS and

(d) rinsing (II) to remove

excess and unreacted species

and form the solid solution

CdS on surface of the

substrate. The coverage of

CdS at higher cycles (e)10

and (f)30

redissolved into chemical bath and QDs films might feel-off from the coating

surface. During first SILAR cycle, the seed layer of QDs was formed on the

coating surface and directing further growth for successive coating cycles. The

influence of coating cycles on growth of QDs can be studied by optical absorption

spectra. Figure

4

a-c explains the influence of coating cycles on optical absorption

of CdS, CdSe [

77

], and Sb

2

S

3

[

78

], respectively. From Fig.

4

a, it is clearly

understood that the absorption of CdS and CdSe is found to increase by gradually

improving the coating cycles. Interestingly, nucleation and growth of CdSe on

TiO

2

can be greatly accelerated with a CdS underlayer, where CdS is rather a

promoter for the preferential growth of CdSe (Fig.

4

b) as it has been also observed

for CBD.

Typically, semiconductor QDs by SILAR process has been demonstrated under

aqueous medium, but the high surface tension causes poor wetting ability on a

solid surface, which leads to poor penetration of the solution in a porous matrix.

Therefore, low surface tension solvent is recommended like alcohol solutions for

efficient QDs coating. Since it has high wettability and superior penetration ability

on the mesoscopic TiO

2

film, well-covered QDs on the surface of mesopores is

achieved easily. The high coverage of QDs results by alcohol solvent showed high

absorbance than that of aqueous solvent (Fig.

4

c).

Search WWH ::

Custom Search