Information Technology Reference

In-Depth Information

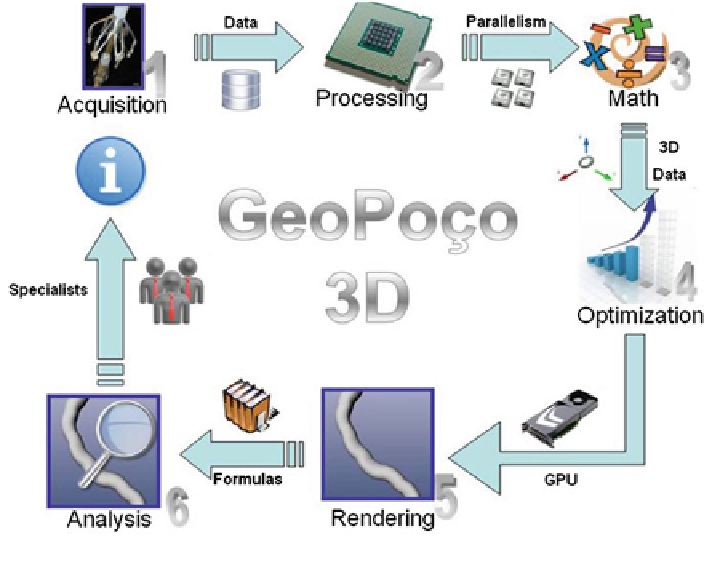

Fig. 13.3

The framework of the 3D Caliper tool (GeoPoço 3D)

13.3.1 Data Acquisition

A borehole failure can be detected by different measurement instruments, like the

following caliper logs: Borehole Geometry Tool; Resistivity logs; Ultrasonic logs.

The caliper tool is inserted into drilling spot to perform a series of measurements

used to evaluate the borehole's feasibility [

1

]. It measures the borehole diameter

variation by depth, i.e., its shape and can also give other important information, as

well hole irregularities or damages. The caliper log can have two, four, or more

extendable arms arranged around the tool. Figure

13.4

shows a simple schema of

the tools and obtained data. Among all these measures P1AZ represents the

alignment of the first arm with the magnetic north in degrees, DEVI represents the

tool's inclination and combined with HAZI gives information about the direction.

All this informations are strictly necessary to reconstruct the borehole geometry,

and these variations on every section will allow the borehole to make curves,

creating the sensation of a real borehole and not just a simple geometric form like a

cylinder.

For each position along the borehole, information such as sensors' position and

orientation, rock's resistivity and acoustic data are obtained. These data allow the

user to find flaws in the soil, leaving to the geologist the decision whether the well

Search WWH ::

Custom Search