Information Technology Reference

In-Depth Information

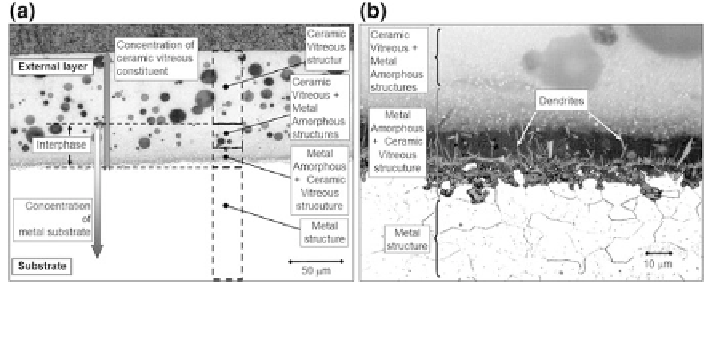

Fig. 9.4 Enamel-steel composite structure. a General micrograph view of the enamel and metal

composite; b detail of the interface between the enamel coating and the metal substrate

internal stresses developed during the firing and cooling phases. In the firing of an

enamel, the sealing at elevated temperatures is accomplished without excessive

stress development because the enamel is relatively fluid at the firing temperatures

and can easily assume the surface dimensions of the metal to which it is applied.

Any difference in the contraction of the metal and the enamel is of little conse-

quence until the temperature is reached at which the cooling rate is too rapid to

allow flow of one on the other or internal flow in either. The stress initially

developed is only a fraction of that which would be expected when considering the

difference in the rates of contraction of metal and enamel. However, as cooling

proceeds, the amount of flow decreases and the rate of stress development becomes

a function of differential contraction rates, moduli of elasticity, thickness, and

shape. To better understand this phenomenon, the expansion curves of both low

carbon-steel and vitreous enamel have to be analyzed.

Referring to Fig.

9.5

, it can be observed that although the metal has a straight-

line thermal expansion relationship with temperature, the curve for enamel is not

straight and undergo a radical change in direction at about the Break Rate Tem-

perature (BRT), which is, in the case of enamel used in the present study, at about

400 C. Therefore, enamel has a lower expansion coefficient than low-carbon-steel

when temperature increases from room temperature. But when the break in the

enamel curve is overcome, the enamel expansion rate increases becoming greater

than the ones of the low-carbon-steel. During this expansion rate change, there is a

small temperature range at which the enamel catches up on the average rate of

expansion of the low-carbon-steel: the primary equivalent rate temperature, shown

in Fig.

9.3

. At the equivalent rate temperature, the rate of expansion of the enamel

and the low-carbon-steel are alike, but the overall expansions at this point are

different. Since the conditions of like expansion and contraction between the

enamel and the low-carbon-steel may occur at other temperature when the enamel

experiences crystallization, contains crystals which invert, or is subjected to spe-

cial heat treatments, these others are called secondary equivalent rate tempera-

tures, shown in Fig.

9.5

. The enamel curves show a drop at F (enamel fusion

Search WWH ::

Custom Search