Information Technology Reference

In-Depth Information

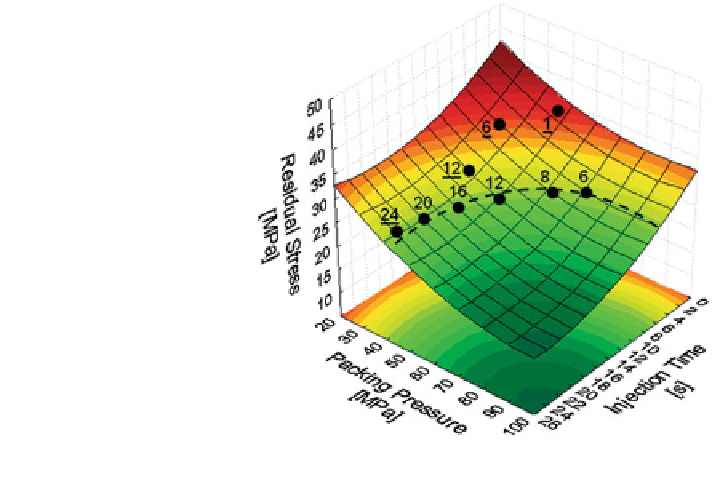

Fig. 8.12 Response surface

obtained using cenítral

composite design, results

obtained through chemical

probe. Tables

8.11

and

8.13

parts which would not be attacked by the acid through low injection times and high

packing

pressure.

Besides,

no

condition

below

this

isoline

should

present

bleaching when attacked with acetic acid.

8.3.2.4 Second Trial

Table

8.12

was designed as follows: Eq.

8.2

was solved taking into account

constant residual stress and equal to 26.05 MPa, a condition required to meet the

hypothesis described above.

The same injection times, molding and injection temperatures from Table

8.13

were used. Packing pressure (equation) was thus obtained. Upon entry of the same

data into the flow rate simulation tool, simulated packing pressure and post-

processed residual stresses are determined.

The highest error between simulated results and those obtained by Eq. (

8.2

)for

packing pressure was 3.6 %, which corresponds to point 20. Five samples analyzed,

corresponding to points 6, 8, 12, 16, and 20 showed no bleaching after treatment

with acid. Electron microscopy analysis with 200 magnification showed no presence

of micro cavities in the order of magnitude observed in the first trial (see Fig.

8.14

).

Process settings of trials of response time in Fig.

8.12

are transferred via analogy.

Taking into account the absence of surface bleaching of this trial, one can state that,

in these conditions, all parts would be adequate for the chrome plating process.

Consequently, the hypothesis of following the isoline would be demonstrated, i.e., it

Search WWH ::

Custom Search