Information Technology Reference

In-Depth Information

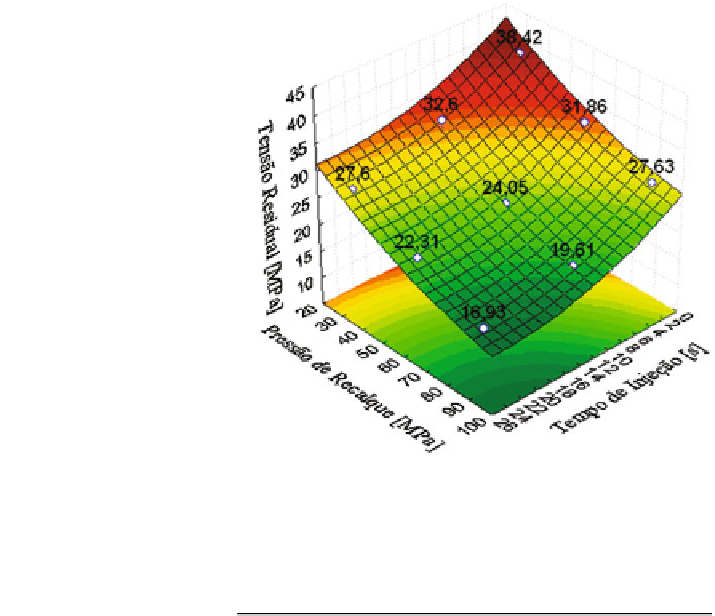

Fig. 8.10 Response surface

do experiment DOE2

Table 8.10 Equation

8.2

coefficients below

Equation

8.2

coefficients

a = 49.109512013923

d = 0.3531409979609

b = 0.9140054624976

e = 0.0013341269841

c = 0.0182262061609

f = 0.00013434089001

nine settings given in Table

8.7

. The key information obtained through the anal-

ysis of Fig.

8.10

is the confirmation of the presence of iso-areas of residual stress

values, previously demonstrated by experiment DOE1. Statistical validation of

experiment DOE2 was carried out through the analysis of the normal probability

chart (Fig.

8.11

), which shows an adequate behavior in relation to the normal ideal

distribution.

8.3.2.3 First Trial

Upon the response surface of Fig.

8.10

, the points corresponding to experiments 1

and 2 which were obtained through the injection molding process, and were

subjected to chemical attack were positioned. Respective settings can be seen in

Tables

8.11

and

8.13

, leading thus to Fig.

8.12

, further discussed.

Table

8.11

shows the main parameters used for the injection of specimens. The

main characteristic is that packing pressure is lower than injection pressure, which

led to different simulated residual stress in the trials.

Search WWH ::

Custom Search