Graphics Reference

In-Depth Information

work. The STL ile is read by the printer's irmware that “slices” up the mesh-

wrapped digital design into thin virtual layers that will correspond to the thin

physical layers that will shortly be 3D printed.

Each virtual slice of an STL ile represents a cross-section of what will

become the inal, printed object. Remember the traced outline of the base of

a coffee cup? That outline would equal to the contour of a single “slice” in an

STL ile and correspond to a single 3D printed layer. After tracing the contour,

the printer will need to raster-scan back and forth to ill-in the interior of the

contour, like illing in the shapes in coloring topic.

Some 3D printers have a built-in visualization tool that double-checks a

CAD to STL ile conversion. In the future, intelligent software will make sure

a design ile can print what its designer intended. In the meantime, experts

like John guide all types of design iles from their digital incarnation into a

sturdy, attractive 3D printed model. “Once a design ile is ready,” John said,

“the hardest work is behind us.”

If the humans did everything right so far, at this point, once a design ile is

ready, the printer should take care of itself. Deep inside the printer, microcon-

trollers and sensors (similar to print drivers in paper printers) tell the machine

what to do to make sure that everything works as it should. John said, “After

you click print, the machines can run unattended overnight.”

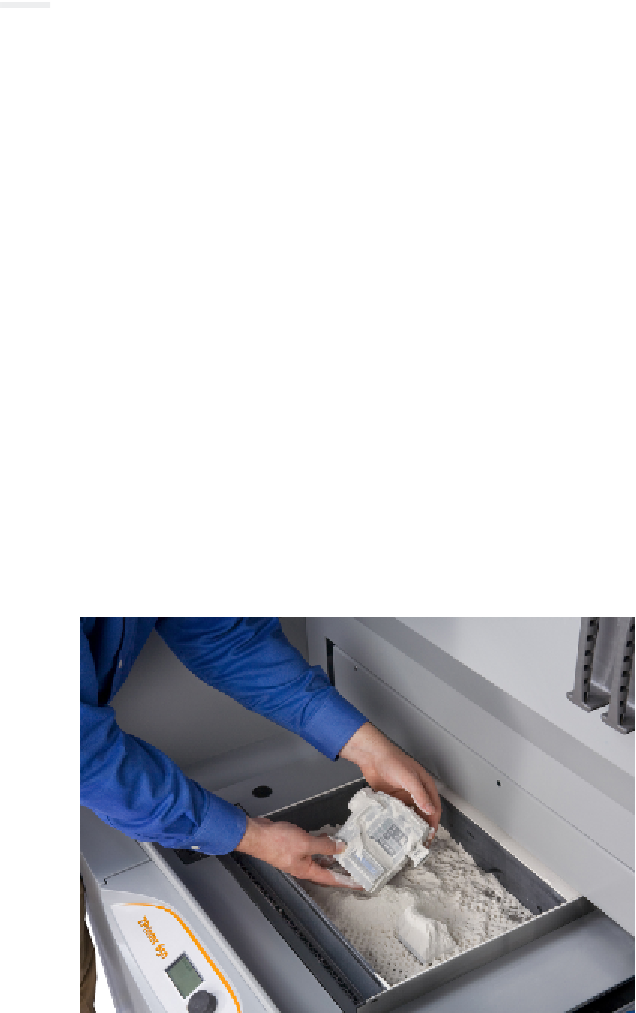

The printed object is unburied from its powder print bed and cleaned up.