Graphics Reference

In-Depth Information

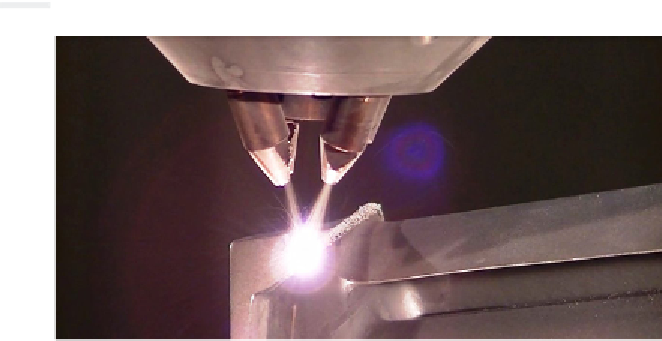

Powdered metal is blown into a laser beam. Particles that hit the focal point

melt and gradually build up a metal part.

Since more than one nozzle can blow powder into the laser beam at the

same time, multiple base metals can be used simultaneously to “print” alloys

(mixed metals) in tunable ratios. The ratio can even be varied depending on

the position of the head, leading to graded alloys.

Laminated object manufacturing (LOM)

Last but not least, another member of the selective deposition printer side of

the family are laminated object manufacturing printers (LOM). LOM printers

don't use a print head to form layers. Instead, LOM printers, like their name

suggests, laminate thin sheets of material into a single solid three-dimensional

objects.

The LOM process begins with a design ile. Instead of a print head, a knife

or laser beam does the work. Following the design ile's guidance, the cutting

tool slices out the contours of a shape from a thin ilm of paper, plastic or

metal. Imagine taking a coffee cup, setting it down on a sheet of paper, and

cutting out its outline in the shape of the cup's base.

After the cutting instrument is done with a sheet, the LOM printer whisks

the cut-out aside and lays out a fresh sheet of adhesive ilm to cut the next lay-

ers. The printer stacks together the cut layers of paper, plastic or metal. When

the cross sections of the object have all been cut out, the printer laminates and

presses the layers of cutouts to fuse them into a solid 3D object. Some models