Graphics Reference

In-Depth Information

Future assemblers may be able to pick up massive numbers of voxels in par-

allel (meaning several at one time) and place them into layers simultaneously,

opening the door to what one day will be “digital materials.” To distinguish

these printers from their analog ancestors, we called these members of the

new generation of machines “rapid assemblers.” The next revolution after 3D

printing will be the transition from analog to digital materials.

Hybrid analog-digital printing

Imagine a future where human-made artifacts are composed of billions of

tiny building blocks. These building blocks each have the same size and

shape, and the same electric and mechanical connectors. Like tiny LEGO

bricks, no larger than 100 microns in size—the size of a pixel on your

screen—they interlock. Each of the two dozen or so building block types

is made separately in bulk, and shipped as powder in a cartridge for an

assembler.

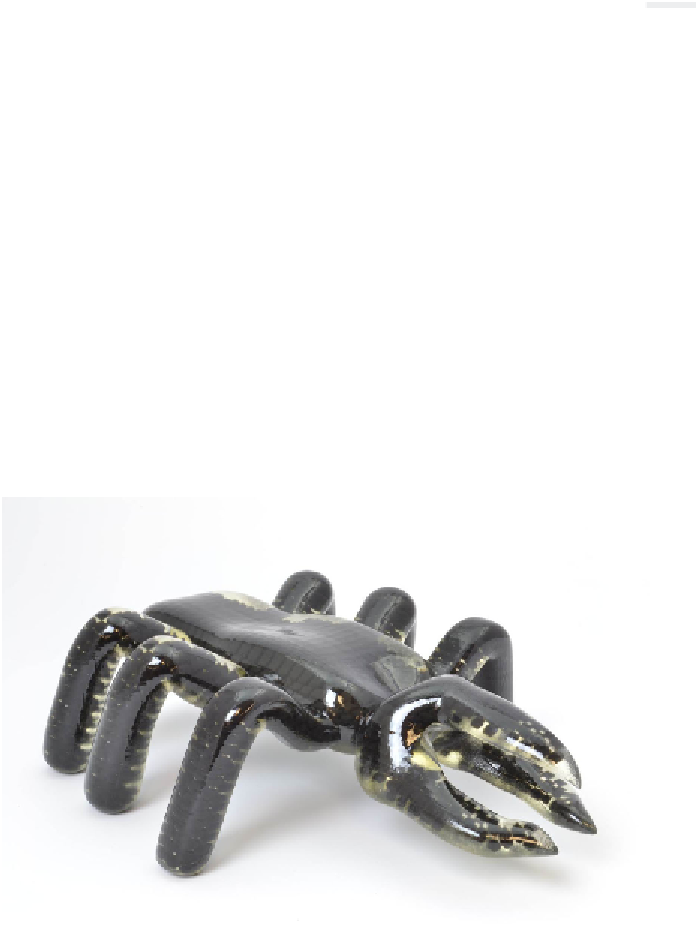

Concept demonstration of hybrid digital-analog print. Body printed in transparent

analog (smooth) material. Inside is a visible digital lattice structure of mock-voxels.