Graphics Reference

In-Depth Information

A computer connected to the D-Shape printer runs CAD software that guides

the robotic arm millimeter by millimeter over a bed of sand.

The D-Shape printer works by extruding liquid adhesive through hun-

dreds of small nozzles onto the bed of sand. The mixture contains a catalyst

the makes the adhesive more quickly bind to the sand. After four passes, the

printed layer solidiies. Fresh sand is sprinkled on top and the robotic arm is

recalibrated so it can deposit another layer of adhesive on top of the irst. It

takes about a day for the printed walls to solidify.

According to Enrico's website, the adhesive is strong and can substitute for

iron as a structural reinforcement. The artiicial stone printed by the D-Shape

printer could be made of any kind of sand and it's stronger and cheaper than

Portland cement. A 3D printed sandstone structure is faster to build than one

made of traditional building materials.

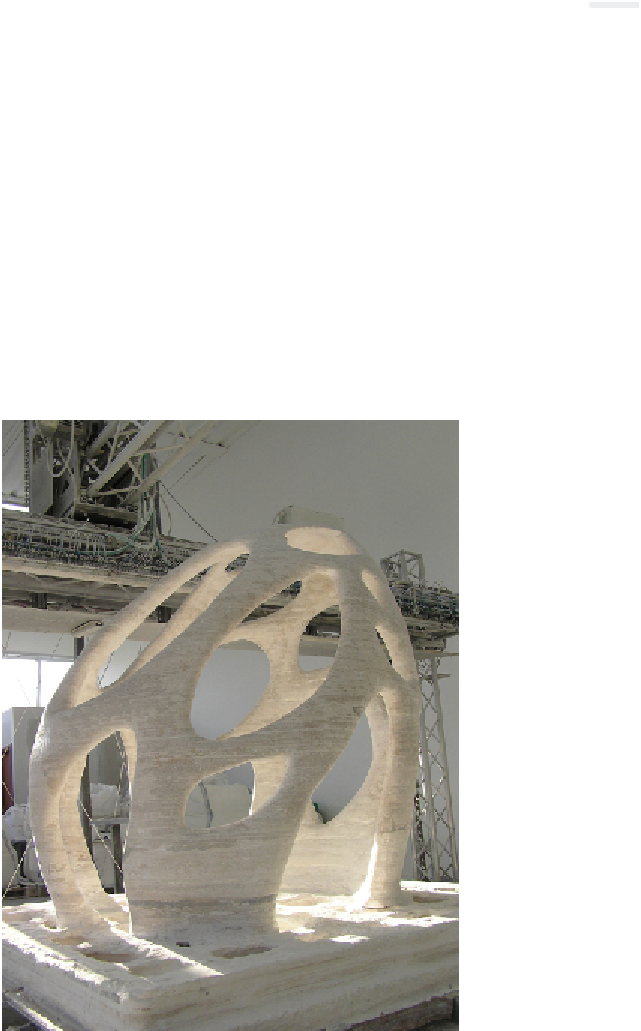

Enrico Dini prints structures out of a blend of sand and adhesives.

The end result is a hard and smooth stone surface. The shapes and

curves would be very dificult to hand carve out of stone or marble.