Graphics Reference

In-Depth Information

when no one is watching. Cake frosting quickly became the most commonly

used sacriicial material for 3D printing projects.

My students and I weren't the only people venturing into 3D food printing.

Several years ago when we launched Fab@home into the world, we expected

that people would build printers and use them to print plastic parts or perhaps

toys or useful things for their homes. Instead, Fab@home users wrote to us to

share stories of printing food. Noy Schaal, a high school student in Louisville,

Kentucky, was one of the earliest users of Fab@home when we open sourced the

machine designs in 2006. With her father Maor, Noy built her own Fab@home

printer and then customized it, adding a heated chocolate extruder.

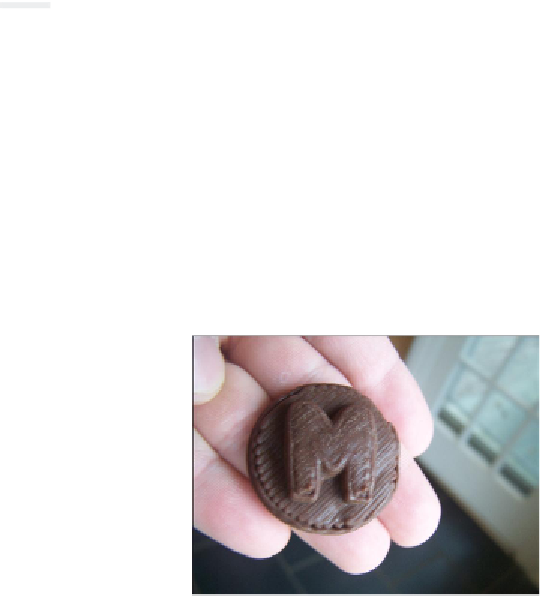

The printed chocolate that won high school

student Noy Schaal irst prize at a high school

science fair in 2006

For several weeks the Schaals experimented with different temperatures

and printing nozzles. Their efforts paid off at the state's high school science

fair where Noy designed and printed chocolate pieces shaped like the state of

Kentucky, securing irst prize.

Like a computer-guided frosting bag

Printing even simple food paste is a thorough workout in applied food engi-

neering. Like many of life's pastimes, 3D printing food is a lot harder than it

looks. Printed food must be made with just the right application of mechanical

force, plus a well-designed digital “recipe” using raw ingredients of the correct

consistency. Raw ingredients must be soft enough to push through a syringe

tip, yet stiff enough to hold a shape after being printed. Add to that the chal-

lenge of dealing with each foodstuff's unique material properties, different

temperature tolerances and different cooking methods.