Graphics Reference

In-Depth Information

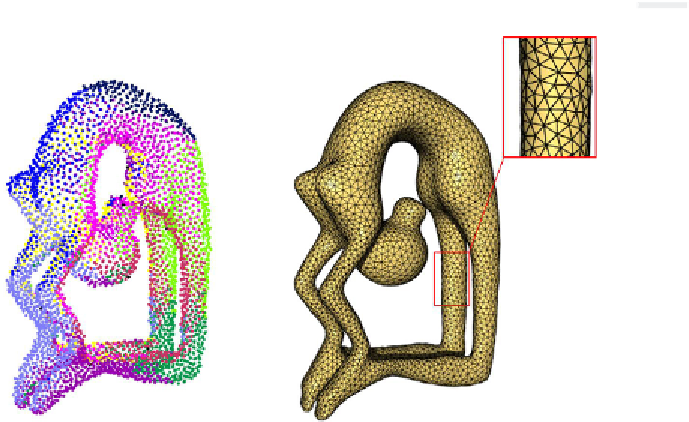

Point cloud data, and a corresponding surface mesh

The bottlenecks are computing power and the lack of algorithms intel-

ligent enough to “ill in the gaps” to complete the details of a digital point

cloud. The computer doesn't necessarily understand what it scanned, so you

can't just scan a vase and ask the computer to make the vase wall a little

thicker, because the computer wouldn't know where exactly the wall begins

and ends and which direction is “thicker.” Like other digital software tools,

optically scanned data doesn't capture an object's insides. This is changing

thanks to improving medical imaging technologies such as CT scanners,

MRIs, and ultrasound.

Why design software can't keep up

Modern design software is still dogged by its roots, by the fact that it grew out

of manufacturing and animation ields that only recently started 3D printing.

The same design tools that were intended to deal with limited amounts of

computing power and save time, money and improve knowledge transfer, ironi-

cally, also place limitations on what can be 3D printed. As a result, a design

ile doesn't depict the detailed insides of physical things (at least without a lot

of additional custom work). Nor can design software graphically model and

predict the behavior of complicated blends of different materials.